2 月 . 03, 2025 02:39 Back to list

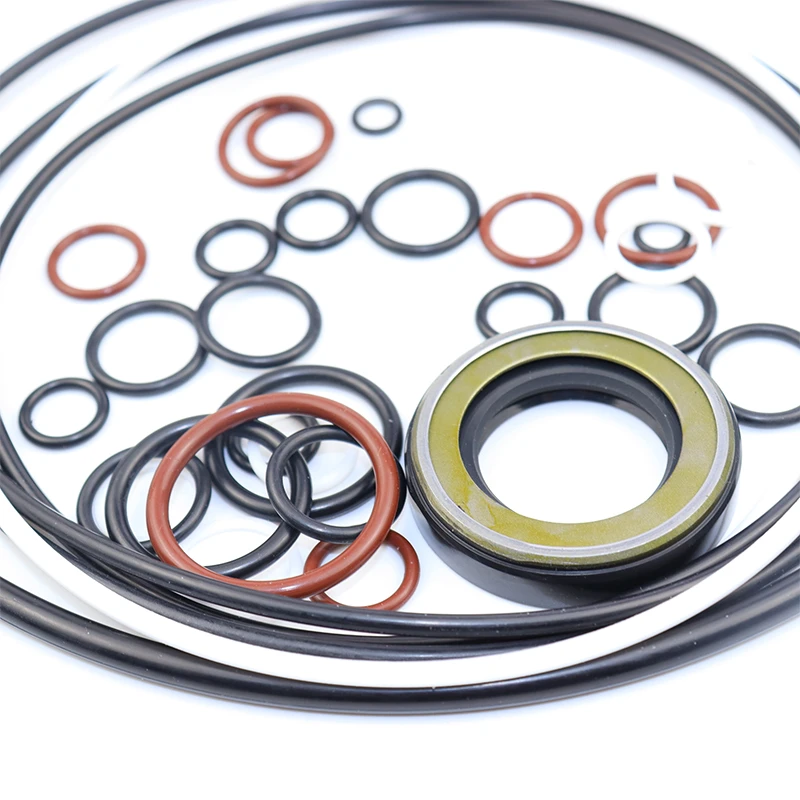

shaft oil seal

Authoritativeness in the context of shaft oil seals connects with the quality standards observed during manufacturing. Reputable manufacturers adhere to stringent industry standards like ISO 9001, which ensures the product's consistency and reliability. Certification from recognized bodies indicates a commitment to quality, crucial for sectors such as automotive, aerospace, and power generation, where operational safety and reliability are paramount. Trustworthiness in shaft oil seals derives from both product performance and the reputation of the supplier. When selecting a supplier, evaluate their track record in delivering high-quality and durable products. Testimonials and client reviews can provide insights into real-world performance and customer satisfaction, making them valuable resources for decision-making. For enhanced machine efficiency, engineers and maintenance professionals should also focus on proper installation and maintenance practices of shaft oil seals. Incorrect installation can lead to instant failure, highlighting the importance of following manufacturer guidelines and using recommended installation tools. Periodic inspections and timely replacements are equally important to maintain optimal machinery performance. In conclusion, the intricacies of shaft oil seal selection and maintenance embody a blend of experience, expertise, authoritativeness, and trustworthiness. A deep understanding of these components enhances the operational efficiency of machinery, contributing to the longevity and reliability crucial for any industrial application. As machinery and equipment continue to evolve, so too must the approaches to selecting and maintaining essential components like shaft oil seals, ensuring seamless and trouble-free operations.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories