2 月 . 03, 2025 02:59 Back to list

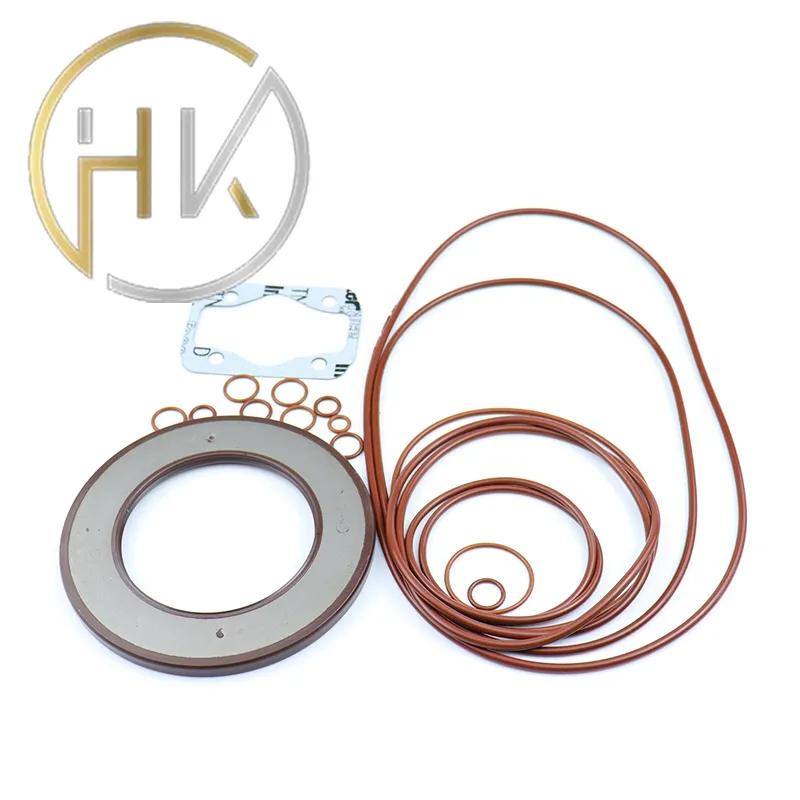

oil seal tcv

Authoritativeness in the context of oil seal suppliers refers to the standing of a supplier within the industry. Suppliers who are recognized leaders often set the benchmark for innovation and quality. They stay at the forefront of technological advancements, adopting cutting-edge manufacturing techniques and rigorous quality control measures. They may also contribute to industry standards through research and development, further solidifying their authoritative position. Partnering with such a supplier guarantees access to the latest technologies and product innovations. Trustworthiness is a critical indicator of a reliable oil seal supplier. Trustworthy suppliers are characterized by their transparency, adherence to ethical business practices, and commitment to customer satisfaction. They provide clear documentation and specifications for each product, ensuring customers know exactly what they are purchasing. Moreover, these suppliers often offer robust warranties and support services, demonstrating their faith in their product's durability and performance. For decision-makers in industries reliant on high-performance machinery, the choice of oil seal supplier is not a decision to be taken lightly. It is a strategic investment into the machinery's operational efficiency and reliability. An experienced, expert, authoritative, and trustworthy supplier can provide custom solutions tailored to meet specific operational requirements, enhancing productivity, minimizing downtime, and reducing maintenance costs. In summary, when selecting oil seal suppliers, prioritize those with a proven track record in the industry, technical expertise, recognized authority, and a reputation for trustworthiness. Such suppliers not only deliver superior products but also augment the overall operational effectiveness of your machinery, ensuring longevity and optimal performance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories