1 月 . 28, 2025 02:28 Back to list

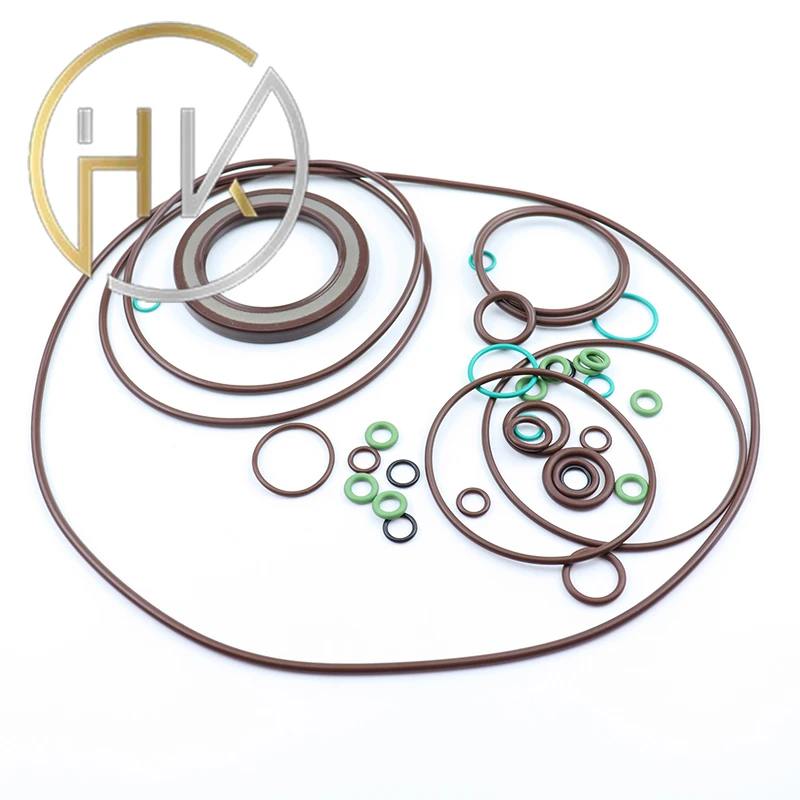

wiper seals

The trustworthiness of rod wiper seals is paramount in settings where failure could result in operational and financial losses. Brands known for rigorous quality testing and compliance with industry standards often lead in market preference. Professionals seeking reliable solutions prioritize products tested under real-world conditions, ensuring that each seal offers the robustness required for specific applications. Insights gathered from professional evaluations of rod wiper seals highlight the importance of proper installation and maintenance. Ensuring correct installation avoids potential leaks and failures, safeguarding the equipment’s operation. Routine inspections and timely replacements are additional practices that enhance trust in the seal’s performance. Innovation in the design and manufacturing processes has also positioned contemporary rod wiper seals on the cutting edge of technology. Manufacturers are increasingly incorporating advanced polymers and sophisticated design techniques to address evolving industrial challenges. Research and development within the sector continue to uncover new formulations capable of withstanding higher pressures and temperatures, thus broadening the scope of applications. Being informed about rod wiper seals and understanding their role is of utmost importance for industries dependent on hydraulic systems. It demands a blend of technical knowledge, field experience, and an unwavering commitment to quality. The authoritative brands in the market not only offer products but serve as partners in maintenance and efficiency optimization. In conclusion, the rod wiper seal is more than just a component; it is a critical element ensuring the resilience and effectiveness of hydraulic and pneumatic systems. With proven expertise and a robust understanding of market-leading products, industry professionals are equipped to make informed decisions, leading to enhanced system performance and reliability. By focusing on innovative developments and maintaining a comprehensive perspective, engineers and maintenance professionals can leverage these seals to their full potential, thereby sustaining operational excellence across diverse industrial landscapes.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories