1 月 . 28, 2025 02:52 Back to list

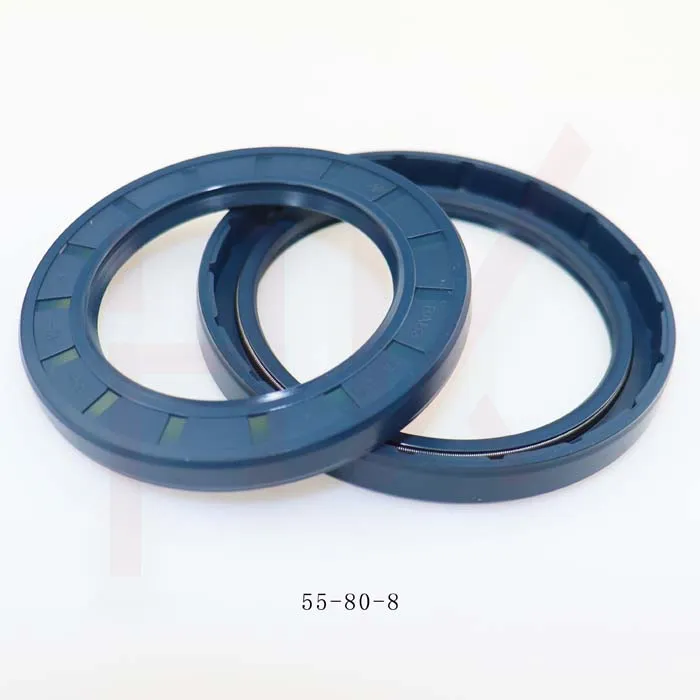

wiper seals

Trustworthiness in the field is built on a foundation of transparency and proactive customer support. Manufacturers and suppliers that offer detailed product documentation, including installation guides, maintenance tips, and longevity forecasts, establish trust with their clients. Furthermore, providing an open line of communication for troubleshooting and support goes a long way in fostering a long-term relationship with customers. Companies should also consider offering training sessions or resources to educate their clients about the significance of maintaining their hydraulic seals and overall systems. Real-world experiences from various industries indicate that investing in high-quality hydraulic wiper seals directly correlates with enhanced operational efficiency. For example, a construction company that experienced frequent downtime due to contaminated hydraulic systems managed to significantly reduce their operational interruptions by switching to premium-grade hydraulic wiper seals. This switch not only prolonged the lifespan of their equipment but also improved project timelines, ultimately leading to better profitability. In conclusion, hydraulic wiper seals might seem like minor components in the grand scheme of hydraulic systems, but their importance cannot be overstated. Their role in preventing contamination and ensuring the system remains sealed effectively helps avoid unnecessary maintenance and prolongs the equipment's operational life. By choosing the right seal type, sourced from authoritative and trustworthy manufacturers, businesses can safeguard their equipment against premature failures and enhance overall system reliability. With a careful selection process and proactive maintenance, hydraulic wiper seals can keep operations running smoothly and efficiently, confirming their critical role in modern industrial applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories