1 月 . 28, 2025 02:07 Back to list

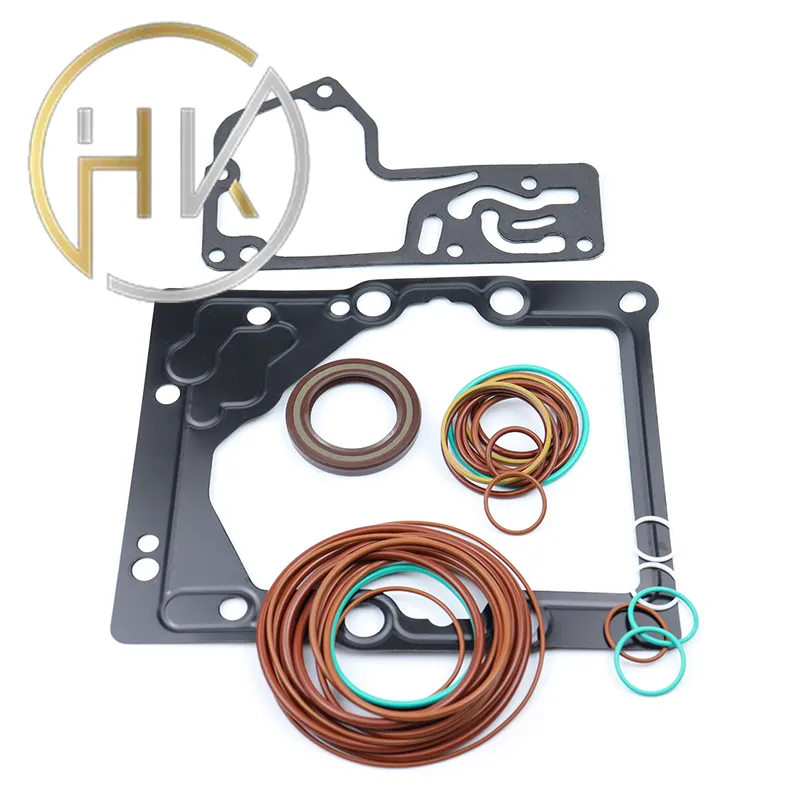

shaft seal wheel hub

Authoritativeness in the realm of shaft seals for wheel hubs can be attributed to those manufacturers who invest heavily in research and development. Companies that lead in this area often collaborate with automotive giants to produce seals that meet stringent industry standards and evolving automobile technologies. Brands recognized for their authoritative stance often provide extensive documentation, certifications, and support to back their products, showcasing a commitment to maintaining high standards within the industry. Trustworthiness is a critical factor when selecting shaft seals for wheel hubs. Reputation builds trust, and manufacturers with a long-standing history of quality and innovation are often preferred. These manufacturers go beyond compliance and often exceed industry standards, providing warranties and support that instill confidence in their products. Trust is also enhanced through transparent business practices, including clear communication with clients and partners about product capabilities and applications. In conclusion, the shaft seal for wheel hubs represents a mesh of sophisticated engineering and practical application necessary for vehicle efficacy. Those involved in the selection and utilization of these components must weigh factors such as material selection, design expertise, brand trustworthiness, and authoritative endorsements. By choosing the right shaft seal, vehicle manufacturers and mechanics ensure not only the safety and performance of their vehicles but also fortify their own standing within the competitive landscape of the automotive industry. Investing in quality shaft seals is not merely a purchase; it's a commitment to excellence in vehicle maintenance and ownership.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories