1 月 . 28, 2025 03:16 Back to list

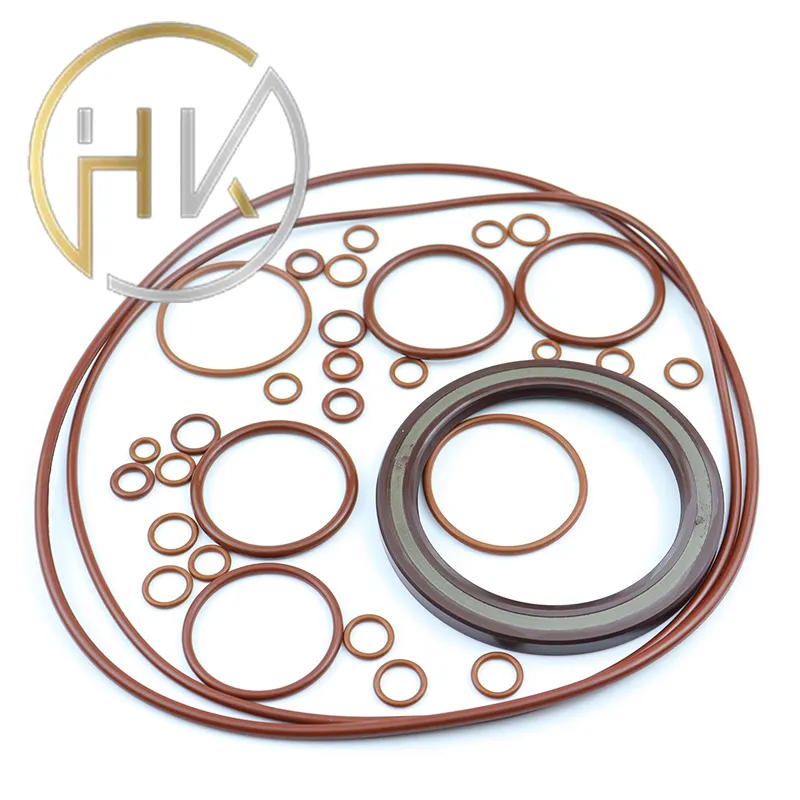

wiper seals

Authoritativeness in the realm of hydraulic systems is built through consistent performance and reliability. Manufacturers of hydraulic cylinder wiper seals often conduct rigorous testing to evaluate their products' endurance under various conditions. These tests simulate real-world scenarios to predict the seal's lifespan and effectiveness within a hydraulic system. By acquiring seals from established manufacturers who emphasize R&D and product testing, businesses leverage the accumulated knowledge and innovation that only seasoned players can offer. Trustworthiness is a critical factor, particularly in industries such as construction, manufacturing, and aerospace, where hydraulic systems play a pivotal role in operations. Companies that rely on these systems must have assurance in the components they use, especially seals, as a failure can result in not just operational stoppages but also safety hazards and financial losses. Trust is built over time, and manufacturers who consistently deliver durable and effective wiper seals gain the confidence of their clients. Testimonials from long-term users and case studies illustrating the performance of these wiper seals in demanding scenarios can be instrumental in building this trust. In the competitive landscape where hydraulic systems are integral, the humble wiper seal stands out as a component that, though small in stature, is large in impact. Businesses that pay attention to the quality and upkeep of their hydraulic cylinder wiper seals can enjoy enhanced performance, reduced downtime, and extended equipment life. As such, understanding the role of wiper seals and applying this knowledge in selecting and maintaining them is a strategic move, underscoring the expertise and authoritative knowledge in hydraulic system management. To conclude, the hydraulic cylinder wiper seal, while seemingly simple, embodies a fusion of experience, expertise, authoritativeness, and trustworthiness. It serves as a testament to the importance of the finer details in engineering and the significant impact they can have on operational success. Emphasizing the right approach to wiper seal selection and maintenance is not merely about ensuring system reliability; it is about advancing towards operational excellence in industries where hydraulic systems are pivotal.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories