2 月 . 18, 2025 01:58 Back to list

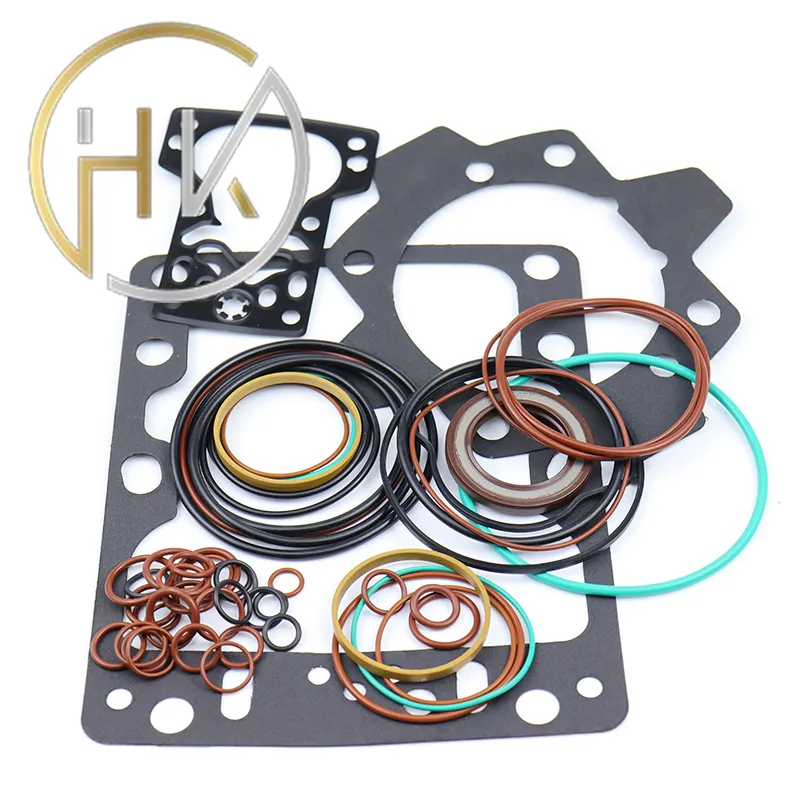

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

In terms of authoritativeness, it's important to consult with reputed manufacturers and suppliers who have a proven track record in the industry. Companies that invest in research and development to innovate better sealing solutions are usually reliable sources for purchasing dust wiper seals. These companies often publish technical data sheets and offer expert consultations which can be invaluable resources for understanding the best seal application for specific needs. Trustworthiness in dust wiper seal selection can further be fortified by looking for products that comply with international standards and certifications. Brands that adhere to ISO standards, for instance, tend to maintain consistency in quality and performance, offering assurance to buyers regarding the product’s reliability. From a consumer perspective, real-world testimonials and case studies offer insightful glimpses into product performance. Feedback from seasoned engineers and technicians who have used specific dust wiper seals provide practical insights that often go beyond theoretical knowledge. Such experience-backed advice can help users make informed decisions that perfectly align with their operational requirements. In conclusion, while dust wiper seals may seem like minor components within complex machinery systems, their role in safeguarding against contamination and ensuring smooth operations is indispensable. Selecting the right seal requires a blend of theory and practical knowledge, supported by insights from experienced professionals and reputable manufacturers. By prioritizing quality, compatibility, and appropriate installation practices, both performance and longevity of equipment can be optimally sustained, safeguarding investments and minimizing unnecessary downtime.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories