2 月 . 18, 2025 01:39 Back to list

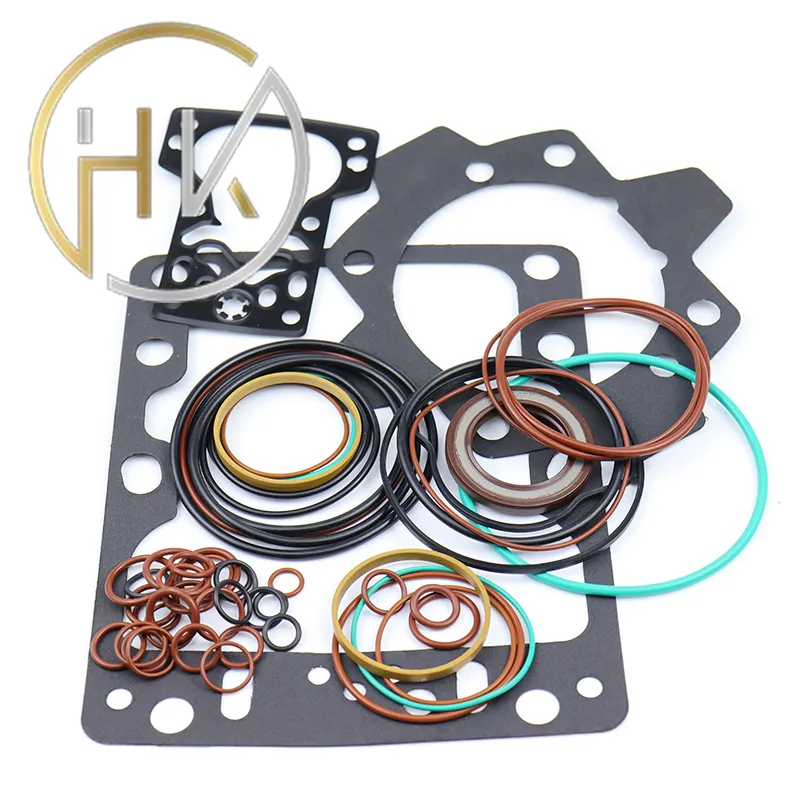

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Trustworthiness is a cornerstone of the wiper seals' reputation. By consistently delivering on performance promises, these seals have gained the trust of mechanical engineers and maintenance professionals worldwide. Testimonials from industry experts frequently highlight the seals' ability to prevent unplanned downtimes, reduce maintenance costs, and protect valuable machinery. This reliability not only safeguards operational efficiency but also contributes to workplace safety by minimizing the risk of hydraulic failures. Furthermore, the continuous advancements in material science and engineering techniques keep pushing the boundaries of what wiper seals can achieve. Cutting-edge research is exploring new composite materials that can further enhance the seals' resistance to wear and tear, providing even longer service lives. Meanwhile, innovative design approaches are optimizing the seal's geometric configurations for better performance in specific applications, such as minimizing leakage in high-pressure environments. Elements of sustainability are also being integrated into wiper seal production. With increasing awareness of environmental concerns, manufacturers are exploring eco-friendly materials and production processes that reduce waste and energy consumption. This shift not only aligns with global sustainability goals but also meets the growing demand from environmentally conscious organizations seeking to adopt greener technologies. In essence, wiper seals epitomize technical excellence and reliability, embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. For industries that rely heavily on hydraulic systems, investing in high-quality wiper seals is a strategic decision. It ensures the longevity and efficiency of their equipment, ultimately supporting robust and sustainable operations. As technology and materials continue to advance, the future of wiper seals promises even greater innovations, accommodating the ever-evolving demands of modern industries while upholding their unparalleled standards.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories