2 月 . 06, 2025 06:25 Back to list

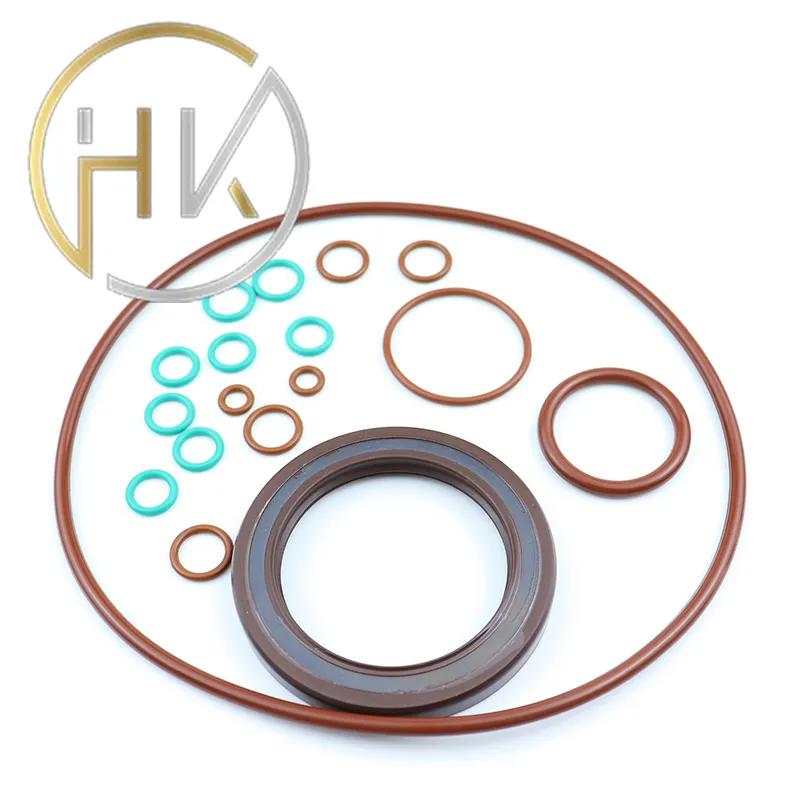

Standard High Pressure TCV Type Hydraulic Oil Seal

Through extensive research and testing, these oil seals have been refined to provide maximum efficiency. Experts recommend regular maintenance checks to ensure seals are in optimal condition, as even the best products can wear out over time. By adopting a proactive maintenance strategy, industries can prevent premature wear and tear, thus avoiding potential downtimes and costly repairs. Authority in the production of oil seals is established through continuous innovation and adherence to industry standards. Leading manufacturers often participate in industry forums and work closely with regulatory bodies to ensure compliance with the latest safety and performance standards. This collaboration not only builds trust but also drives the development of oil seals that meet the ever-evolving needs of modern machinery. Trustworthiness is a cornerstone of any durable product, and oil seals are no exception. Customers rely on well-documented case studies and testimonials that highlight the seal's performance in various environments. This real-world feedback is crucial for maintaining trust and improving products continually. Furthermore, reliable customer service and warranty offers from manufacturers further bolster consumer confidence in their products. In conclusion, the 40 80 10 oil seal is not merely a part of machinery but a critical asset that safeguards operations across industries. Its design and functionality exemplify the pinnacle of modern engineering, offering resilience, efficiency, and cost-effectiveness. For industries looking to optimize their machinery's performance, investing in high-quality oil seals is not just beneficial but essential.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories