2 月 . 06, 2025 06:03 Back to list

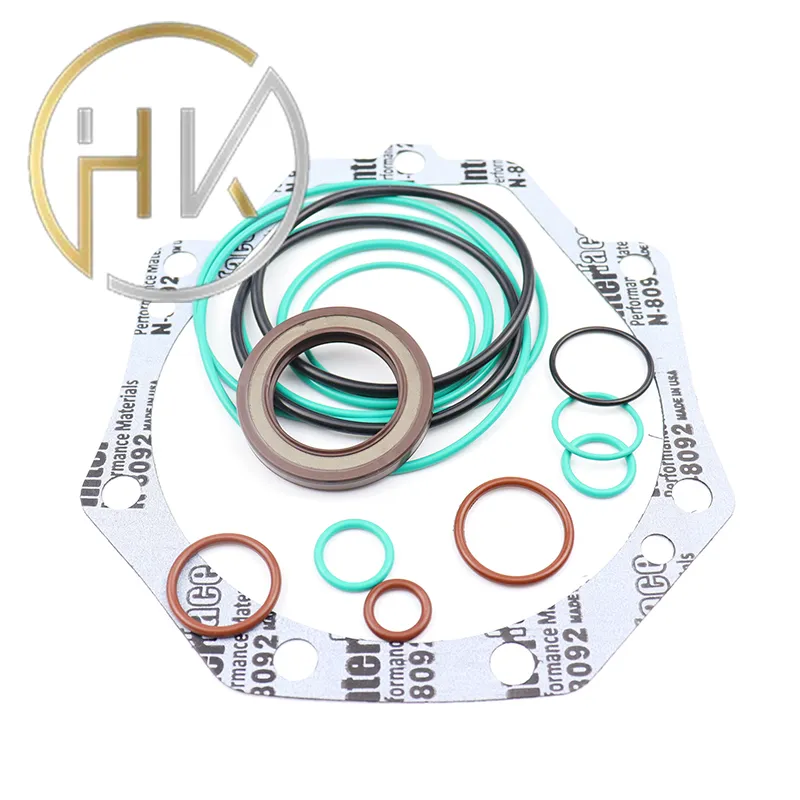

Standard High Pressure TCV Type Hydraulic Oil Seal

Installation expertise is also integral to ensuring the seal performs as intended. A professional setup minimizes the risk of leakage, misalignment, and premature wear. Proper installation involves ensuring that the shaft and housing surfaces are clean and free from damage, as well as using the correct lubrication during the assembly to avoid friction-related challenges. In terms of authority and trustworthiness, North America and European manufacturers often lead the market with seals that meet stringent industry certifications. These certifications guarantee that the seals are manufactured to the highest standards, offering reliability verified through rigorous testing processes. Moreover, real-world experience further underscores the efficacy of the 38x52x7 oil seal. Users in heavy-duty industries have reported enhanced machinery performance and longevity by implementing these seals, demonstrating their capacity to operate under both standard and adverse conditions. The endorsements from industry professionals who have repeatedly chosen these seals for their reliability contribute to their authoritative market position. In conclusion, the 38x52x7 oil seal embodies a blend of precise engineering and robust design, rendering it indispensable in various high-pressure applications. It reflects a synthesis of technical expertise, ensuring that each seal delivers optimal performance, proving its worth in extending the lifespan of mechanical systems. With its outstanding track record in reliability and efficiency, the 38x52x7 oil seal continues to be a trusted component across industries, maintaining its status as a benchmark for others in the field.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories