2 月 . 05, 2025 03:20 Back to list

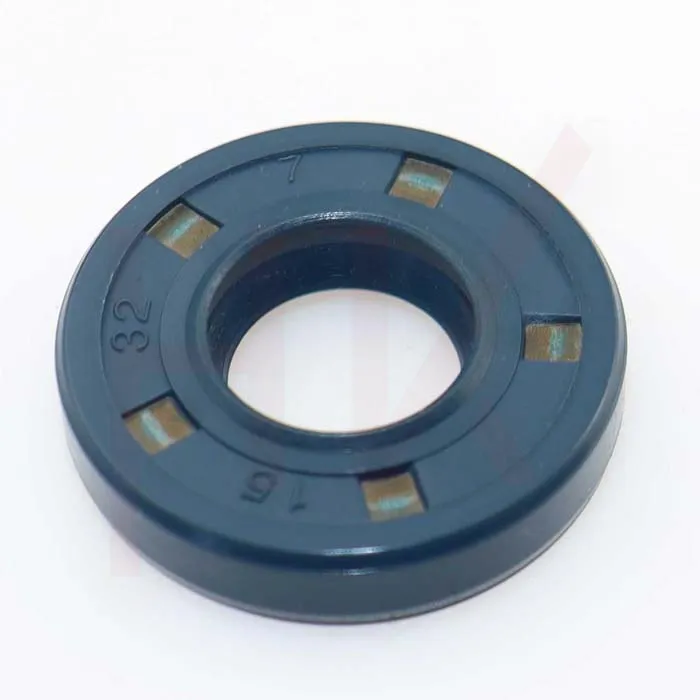

oil seal tcv

From an expert perspective, installation precision is as critical as the oil seal selection itself. Misalignment or incorrect fitting can lead to seal failure, leakage, and damage to the shaft or housing. Experts recommend utilizing proper installation tools and techniques to ensure that the seal is seated evenly and securely. Regular inspections and maintenance are advised to detect any signs of wear or damage early, thereby preventing potential failures. In terms of authoritativeness, the 14x28x7 oil seal has had its efficacy proven across various industries. Its systematic application in renowned industries and backing by industry standards underscore its reliability. Trust in this component is reinforced by decades of successful deployment globally, making it a trustworthy choice for engineers and maintenance professionals alike. Users and technicians report a high level of trustworthiness for the 14x28x7 oil seal due to its performance consistency. Testimonials from mechanical experts often highlight the seal’s robust performance even under strenuous conditions, maintaining functionality over long durations without degradation. This consistent reliability fosters confidence among users, affirming the seal's place as a preferred component in complex mechanical assemblies. To conclude, the 14x28x7 oil seal, with its precise engineering and versatile application, is an indispensable part of modern machinery. Its role in preventing leaks and maintaining operational integrity is paramount, enhancing both the efficiency and sustainability of mechanical systems. By aligning expert knowledge with practical experience, professionals can optimize their use of the 14x28x7 oil seal, ensuring equipment runs smoothly and efficiently, thereby contributing positively to the bottom line.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories