2 月 . 05, 2025 03:42 Back to list

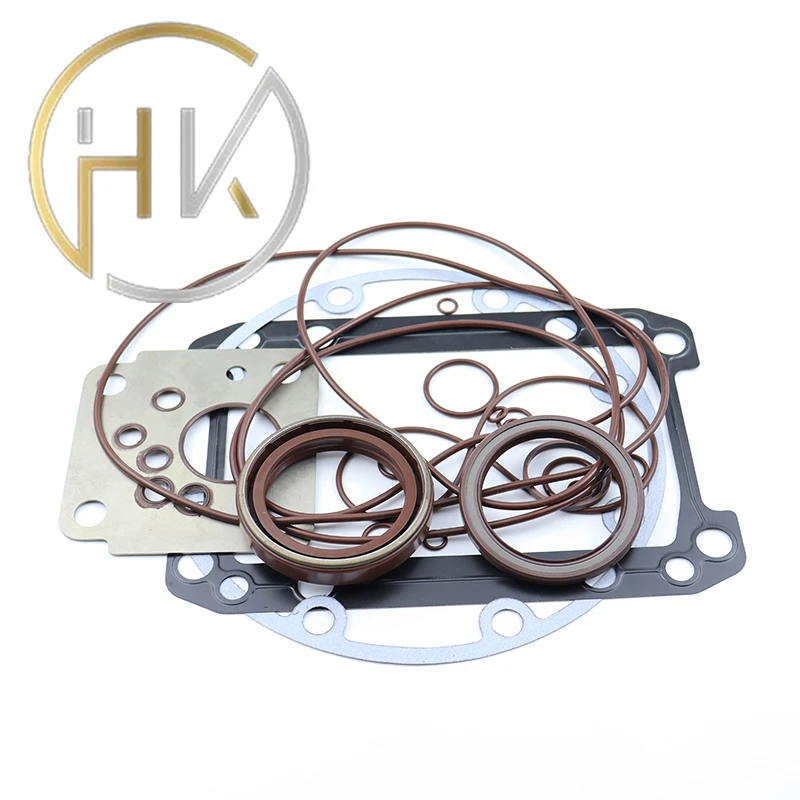

oil seal tcv

Authoritativeness in the industry ensures that the 17x30x7 oil seal adheres to specific standards and quality benchmarks. It's crucial that these components meet criteria set by international bodies, which ensures they perform effectively and safely. This includes compliance with ISO standards which governs their manufacturing and performance parameters. Industries rely on these standards to stock their machinery with components that won't compromise on safety or efficiency. Trustworthiness in oil seal production is non-negotiable. Leading manufacturers offer not only products but also warranties and technical support to uphold their product's reliability. When sourcing a 17x30x7 oil seal, it's imperative to consider a supplier’s reputation and adherence to quality standards. Engaging with manufacturers who are renowned for their technological advancements and customer support can mitigate risks related to seal failure, which can lead to machinery breakdowns and costly repairs. Field experience plays a critical role in understanding the practical applications of the 17x30x7 oil seal. Industry veterans who have utilized these seals can attest to their endurance in real-world conditions. Testimonials and case studies often highlight scenarios where these seals have excelled under pressure or failed due to misapplication, offering valuable insights for optimization. For a consumer or a professional in this field, such shared experiences can guide better purchasing and operational decisions. In conclusion, the 17x30x7 oil seal is a testament to engineering precision and industrial necessity. Its role in safeguarding machinery from fluid leaks and contamination is vital across numerous sectors. When procuring these seals, understanding their material composition, application, and the credibility of the manufacturer ensures they meet the rigorous demands of modern equipment. Thus, with the right knowledge and resources, the 17x30x7 oil seal can serve as a reliable component in extending the operational life of machinery, maintaining efficiency, and reducing maintenance costs.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories