2 月 . 14, 2025 07:15 Back to list

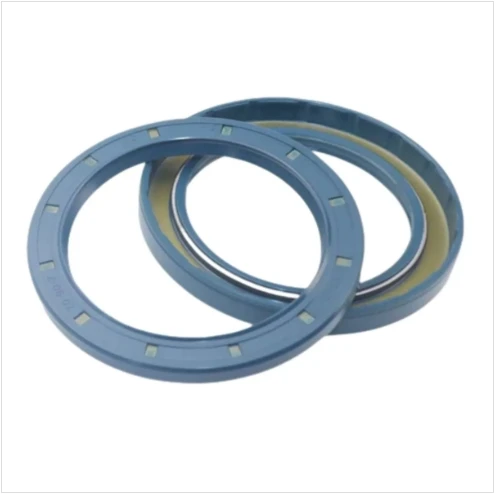

wiper seal types

Double-lip wiper seals present a unique advantage by incorporating two sealing lips instead of one. This design not only enhances the wiping action but also provides redundant sealing, which is beneficial in environments exposed to severe contamination. By providing an extra layer of defense, double-lip wiper seals are often used in construction equipment and agricultural machinery, where they are exposed to considerable amounts of debris. The material composition of wiper seals also plays a crucial role in their effectiveness. Polyurethane is widely used due to its excellent abrasion resistance and superb operational temperature range. For applications exposed to chemicals or extreme conditions, seals made from Viton or PTFE are often recommended, as they offer superior chemical resistance and performance consistency across a broad spectrum of temperatures. When selecting a wiper seal, it's imperative to consider the specific requirements of the machinery it will serve. Factors such as operational speed, the nature of the contaminants, environmental conditions, and the type of hydraulic fluid used can all influence the choice of a suitable wiper seal. Consulting with a seal manufacturer or a hydraulic systems expert can provide valuable insights tailored to the unique demands of a given application. Moreover, proper installation and regular maintenance of wiper seals are as critical as selecting the right type. Ensuring the seal is installed correctly will prevent misalignment and potential seal failure, while routine inspections can catch early signs of wear or damage before they escalate into larger issues. In conclusion, wiper seals might seem like a minor component within the grand scheme of hydraulic systems, but their significance is paramount. By thoroughly understanding the different types and their specific applications, operators and technicians can ensure the continuous, efficient, and trouble-free performance of their machinery. Thus, investing time and resources in selecting and maintaining the right wiper seal is not just advisable—it's essential.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories