2 月 . 14, 2025 06:39 Back to list

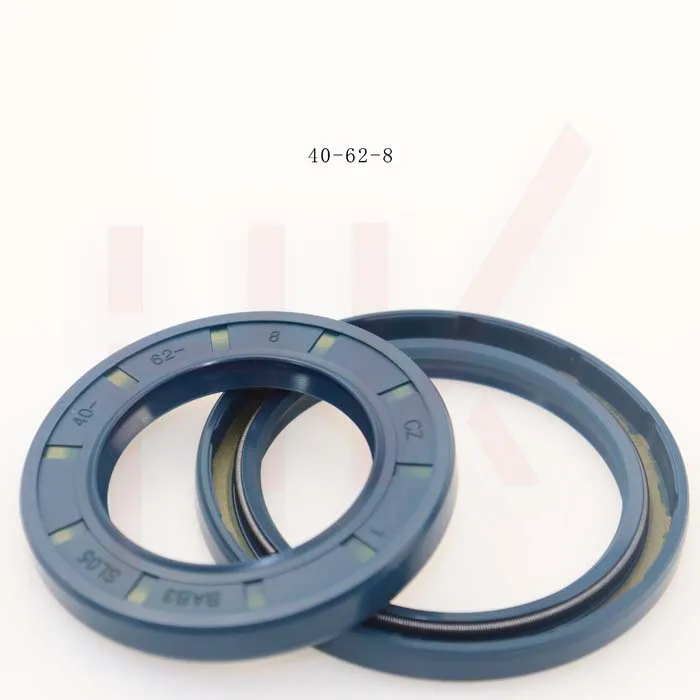

wiper ring seal

The credibility of wiper ring seal manufacturers is also a significant consideration. Reputable manufacturers often conduct extensive research and testing to ensure their seals meet industry standards and offer maximum durability and performance. Choosing products from such companies not only assures quality but also enhances the reliability and lifespan of the equipment being used. From a trustworthiness perspective, one should seek out products that have received certification from recognized bodies. Certifications such as ISO 9001 or industry-specific accreditations can provide peace of mind that the product has been rigorously tested and meets high-quality standards. In addition to certifications, user testimonials and case studies should not be overlooked. Real-world experiences and feedback can provide invaluable insights into the seal’s performance and durability in specific applications. Looking forward, advancements in sealing technology continue to yield innovative developments. These include seals with enhanced wear resistance, the ability to withstand higher temperatures and pressures, and even self-lubricating properties. As industries demand greater efficiency and dependability from their machinery, wiper ring seals are poised to play an even more critical role, driven by continued innovation and heightened performance criteria. In conclusion, the strategic selection and integration of wiper ring seals into mechanical systems are paramount for ensuring operational success. By understanding the nuances of material selection, seal design, and manufacturer credibility, businesses can mitigate risks and enhance the reliability of their operations. As technology continues to evolve, staying abreast of new developments and innovations within the realm of sealing solutions will be key to maintaining a competitive edge in the marketplace.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories