2 月 . 14, 2025 06:11 Back to list

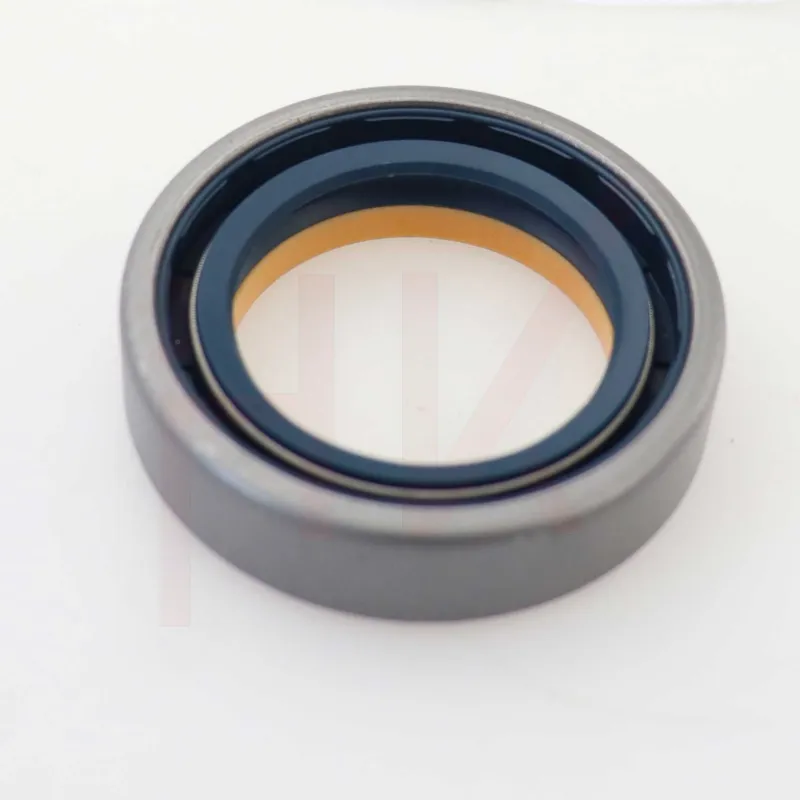

wiper seals

Installing or replacing wiper ring pistons calls for a deep understanding of engine dynamics. Many novices might overlook the necessity for exact fitting and seating to avoid engine inefficiency or damage. Expert mechanics employ digital calipers and micrometers, ensuring each ring matches the manufacturer's specifications and maintains the engine's compression integrity. This meticulous attention to detail underscores the important balance between practicality and precision, essential for the authoritative claims made by trusted mechanics. Wiper ring pistons are not merely isolated components; they provide a bridge to broader considerations of engine buildup and maintenance. Automotive engineers equipped with extensive knowledge work closely with manufacturers to refine these components continuously. Their research and practical experiences infuse each piston design with authoritative insights, ensuring optimal performance across a diverse array of vehicles. Finally, maintaining a transparent relationship with vehicle owners regarding the role and maintenance of wiper ring pistons is crucial for fostering trust. Enthusiasts and professionals alike disseminate their authentic experiences, advising on the best brands, installation practices, and potential pitfalls to look out for. Such transparency and shared knowledge fortify trust between consumers and those who service their vehicles. In crafting a holistic understanding of wiper ring pistons, industry-enriched expertise combined with real-world experiences shine through. The automotive world becomes a bit clearer, the choices a bit more informed, and the roads ever more inviting with the right knowledge at one's disposal. Through these lenses of experience and authority, understanding the nuanced world of the wiper ring piston equips enthusiasts and experts to make informed decisions, ensuring their engines run efficiently and last longer.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories