2 月 . 08, 2025 00:49 Back to list

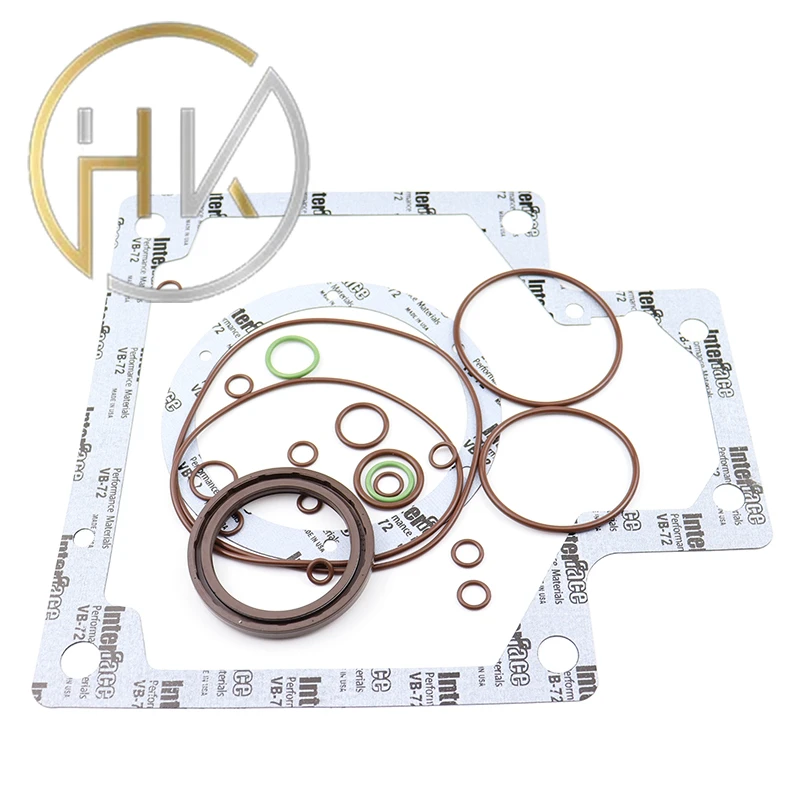

wheel seal oil

From an experiential viewpoint, routine checks and maintenance play a crucial role in ensuring the continued effectiveness of wheel seal oil. Regular inspections should consider signs of leaking oil, unusual noise, vibrations, and increased friction as these could indicate a failing wheel seal. Addressing these issues early with a professional can save significant time and expenses down the line. Additionally, implementing a rigorous maintenance routine conducive to frequent checks of oil levels ensures that the wheel seals continue to function optimally. The authoritative use of data can further reinforce why investing in high-quality wheel seal oil is necessary. Studies have shown that vehicles with optimally performing seals consume less fuel due to reduced frictional losses. Moreover, wheel seals prevent costly repairs caused by bearing failures. Thus, allocating resources towards superior-grade wheel seal oil, though seemingly an additional upfront investment, will result in long-term financial savings and enhanced vehicle performance. The trustworthiness of the chosen wheel seal oil brand is another critical aspect. Established brands with a track record of quality assurance and compliance with international standards provide a layer of confidence. Reading reviews and recommendations from industry experts and fellow consumers can help in making an informed decision. Furthermore, consulting with automotive professionals or referring to manufacturer guidelines ensures that the wheel seal oil fits the specific needs of the vehicle or machinery. In summary, wheel seal oil is more than just a product; it's a crucial element in maintaining the balance between efficient machine operation and longevity. By entrusting this task to capable hands and selecting reliable products, you enhance not just the durability of the wheel assembly but also the overall safety and efficiency of the vehicle. By integrating expertise, authentic experiences, quality assurance, and reliable recommendations, selecting the right wheel seal oil becomes a strategic decision with lasting benefits.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories