2 月 . 10, 2025 11:41 Back to list

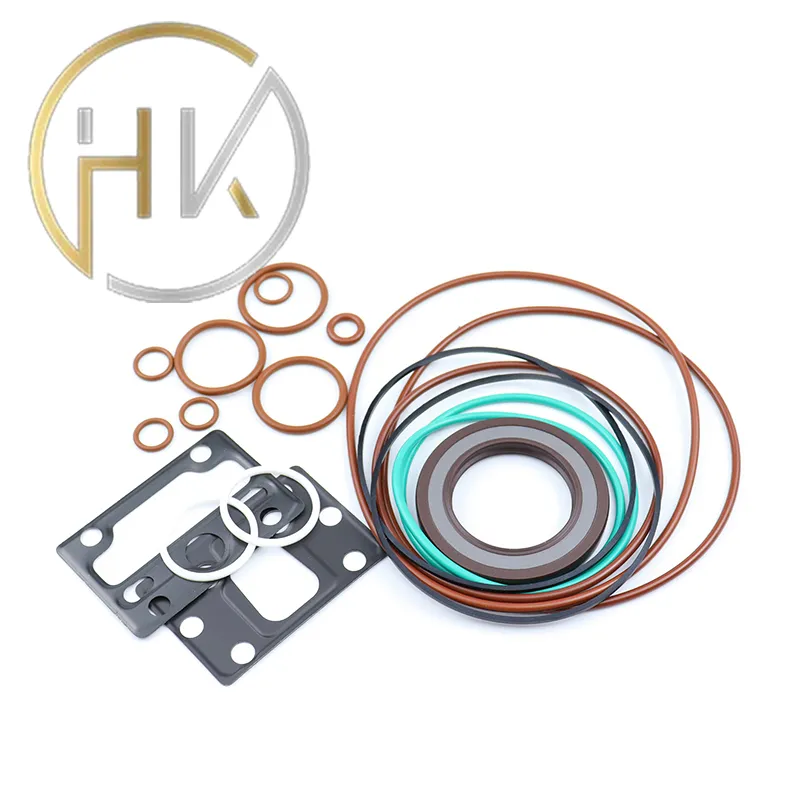

oil seal tcv

On the authoritativeness front, referencing manufacturer guidelines and industry standards (such as those set forth by the Society of Automotive Engineers) offers reassurance. Notably, adhering to these guidelines not only helps in choosing the right seal but also enforces best practices in installation and maintenance, reducing downtime and costly errors. Trust in wheel oil seals is further built through regular inspection and maintenance. Periodic evaluations reveal telltale signs of wear, such as hardening, cracking, or distortion of the seal lip, which could jeopardize their sealing performance. Engaging in predictive maintenance, supported by condition monitoring tools, enhances trust in the seal's reliability and prevents catastrophic equipment failures that could arise from undetected seal deterioration. In response to global sustainability initiatives, the development of environmentally friendly seals, built from biodegradable and recyclable materials, is on the rise. This advancement not only deliberately addresses environmental concerns but also positions manufacturers as forward-thinking leaders in the field of industrial sealing solutions. Ultimately, embracing a comprehensive understanding of the factors affecting wheel oil seal selection, installation, and maintenance elevates consumer confidence and product satisfaction. It armors businesses and operators with the knowledge required to keep their machinery at peak performance while reducing operational risks and costs. In an ever-evolving technological landscape, staying informed about advancements in seal technology is indispensable for those who wish to maintain a competitive edge and ensure the reliability and efficiency of their mechanical systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories