2 月 . 17, 2025 22:15 Back to list

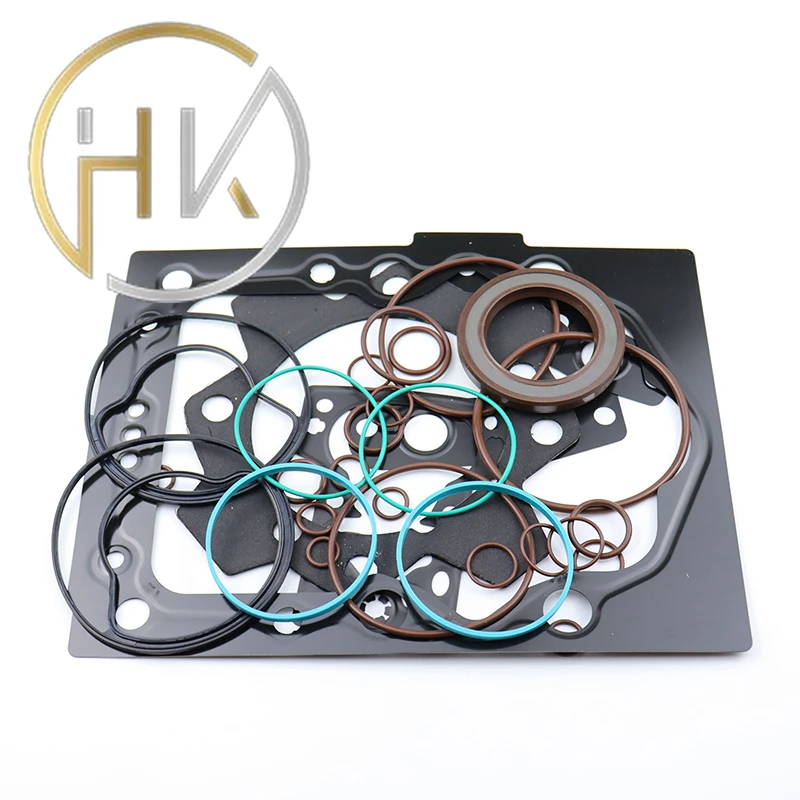

oil seal tcv

Experts understand that the choice of oil seal can influence machinery performance. Different applications demand different types of oil seals, each designed to handle specific conditions such as pressure differentials, temperatures, and the nature of the fluid being sealed. Engineers and maintenance professionals must consider these variables, choosing the right oil seal design to match the needs of their machinery. For instance, applications involving high-speed rotation or temperature extremes may require oil seals made from advanced materials, such as fluorocarbon, due to their superior resistance to harsh environmental conditions. Beyond industrial machinery, oil seals are a fundamental component in automotive engineering. In car engines, oil seals are strategically placed to retain engine oil within the needed compartments and prevent contamination from damaging the engine. The efficiency and longevity of car engines largely depend on the integrity of these seals. Automotive engineers emphasize the importance of regular oil seal inspections during maintenance checks to avoid potential engine failures and promote vehicle safety. Businesses dealing with mechanical equipment recognize the cost-effectiveness of maintaining high-quality oil seals over replacing major mechanical parts due to failure. By investing in reliable oil seals, companies can significantly reduce maintenance costs. This approach not only extends the operational life of machinery but also enhances productivity by minimizing unscheduled downtimes. In conclusion, the function of an oil seal extends far beyond simple sealing. Its role in preserving the performance and integrity of machinery is critical, underscoring the need for careful selection and regular maintenance. As the frontline defense against leakage and contamination, oil seals demand attention from experts aiming to maximize machinery efficiency and longevity. Understanding their importance is not just the prerogative of engineers, but also critical for anyone involved in machinery operation and maintenance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories