2 月 . 17, 2025 22:43 Back to list

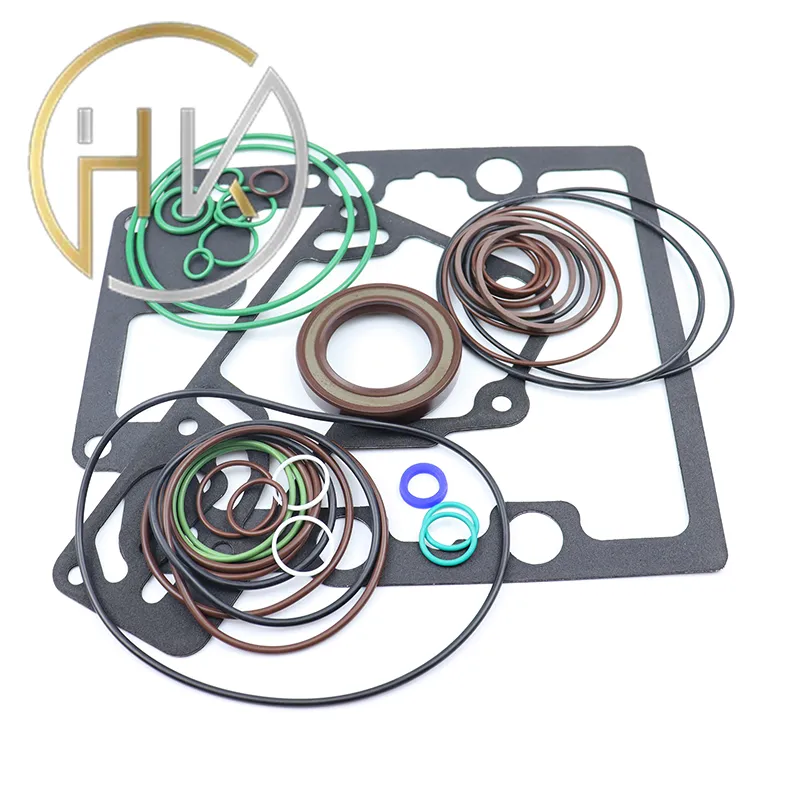

oil seal tcv

In terms of design, the inclusion of features such as lips or ridges can enhance a dust seal's performance by effectively channeling away debris. Experts recommend custom-designed seals tailored to the specific needs of the machinery rather than relying on generic options, as this customization can lead to significant improvements in durability and efficacy. Authoritative bodies and trust through certification also play a pivotal role in the reliability of dust seals. Organizations such as ISO provide standards that ensure products meet rigorous quality and operational benchmarks. This certification serves as a testament to the product's robustness and efficacy, fostering trust among consumers and businesses. Investing in dust seals that comply with these standards is a reflection of a commitment to quality and reliability. Furthermore, real-world experiences from industry professionals reveal that regular maintenance, coupled with high-quality dust seals, markedly elevates machinery performance. Proactive replacement of worn seals prevents escalation into more severe mechanical problems, highlighting a preventive approach that a seasoned expert would advocate. In conclusion, dust seals are essential protective components across various industries, ensuring the longevity and efficiency of machinery. Their effective use underpins high operational standards and can significantly mitigate risks associated with equipment failure. Expertise in selecting the appropriate materials and designs, coupled with adherence to recognized standards, reinforces the authority and trustworthiness of these indispensable products. By harnessing the potential of dust seals, industries can safeguard their investments and maintain high levels of productivity and safety.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories