1 月 . 20, 2025 09:11 Back to list

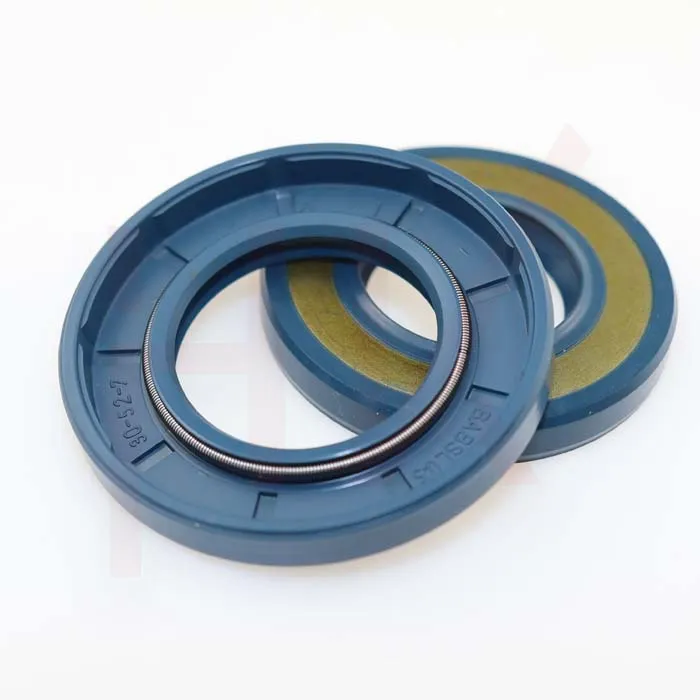

oil seal tcv

Trusting the TCN type oil seal is grounded in its track record of success. Corporations focusing on heavy-duty applications, including energy sector entities and automotive giants, report substantial savings not merely from reduced maintenance costs but also from enhanced machinery productivity. The seals help maintain a pristine condition of lubricant oil, contributing to cleaner engines and smoother mechanical operations. Accurate installation of the TCN type oil seal is paramount for maximizing its efficacy. Professional guidance suggests paying meticulous attention to the seal’s size compatibility with the housing bore and shaft diameter. Moreover, lubrication is critical during installation to prevent damage and ensure a seamless seating. Proper alignment minimizes the risk of leaks and prolongs the service life of both the seal and the machine components it protects. The market for TCN oil seals is supported by ongoing research and development; manufacturers are continually enhancing these seals' materials and design to cater to evolving industrial needs. Innovations include improvements in wear resistance and reduction in friction, positioning the TCN type oil seal as a forefront choice for future industrial advancements. Despite their robustness, TCN oil seals should undergo regular inspections. Maintenance teams should watch for signs of wear, misalignment, or chemical degradation. Early detection of potential issues can prevent significant mechanical failures, making regular inspections a judicious practice in maintaining operational integrity. In conclusion, the TCN type oil seal exemplifies a product combining experience-backed efficiency, expert engineering, authoritative industry approval, and trustworthy performance. It not only meets the rigorous demands of contemporary machinery but anticipates future challenges within industrial ecosystems. For entities intent on optimizing their mechanical operations, investing in TCN oil seals signifies a step toward sustainability and enhanced productivity.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories