1 月 . 20, 2025 08:42 Back to list

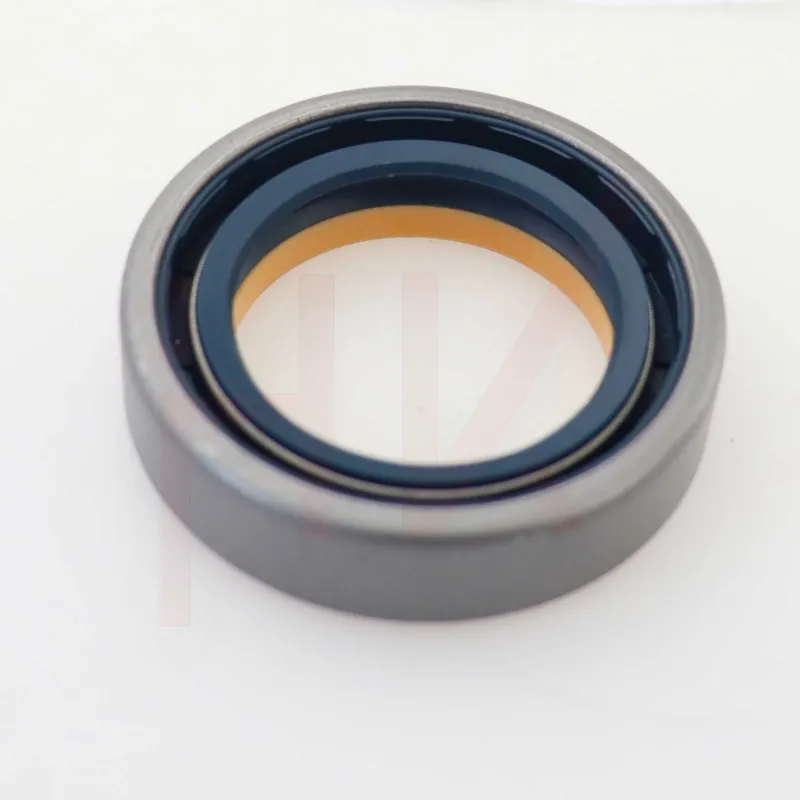

oil seal tcv

To further cement TCN oil seals as a leading authority in the market, the manufacturing process is subject to rigorous quality assurance protocols. This commitment to excellence ensures that every seal dispatched meets global industry standards. Laboratories testing for endurance, tensile strength, and temperature resistance back up the claims of superior performance. The presence of certifications from recognized bodies further boosts confidence in their authority as a credible product. Choosing the right oil seal, experts argue, is not just a matter of brand preference but an informed decision based on specific application demands. TCN oil seals are often recommended by consultants for their knack for reducing friction and minimizing wear, crucial factors that influence machine efficiency and energy consumption. Over time, less friction directly correlates with reduced power requirements and longer lifespan of machinery components. Trustworthiness, a key indicator of a product’s standing in the market, is notably associated with TCN oil seals within the community of engineers and maintenance experts. The consistency with which these seals perform, coupled with positive user feedback, strengthens their position as trustworthy components. As an investment, companies feel secure in choosing TCN oil seals, attributing their decision to the combination of durability and cost-effectiveness, a blend that promises excellent return on investment. In a world where machinery downtime can spell substantial losses, the role of TCN oil seals becomes even more crucial. Their deployment in strategic sectors provides assurance of uninterrupted operations, a promise that is backed by decades of manufacturing expertise and customer satisfaction. In conclusion, the stature of TCN oil seals is evident through their widespread application across diverse industries and their ability to meet and exceed performance expectations. Their presence in critical systems is a testament to their engineered perfection, standing as a beacon of innovation and reliability in fluid sealing technology. Companies and engineers seeking a solution that merges cutting-edge technology with practical application will find TCN oil seals an indispensable ally in their quest for operational excellence.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories