2 月 . 03, 2025 00:33 Back to list

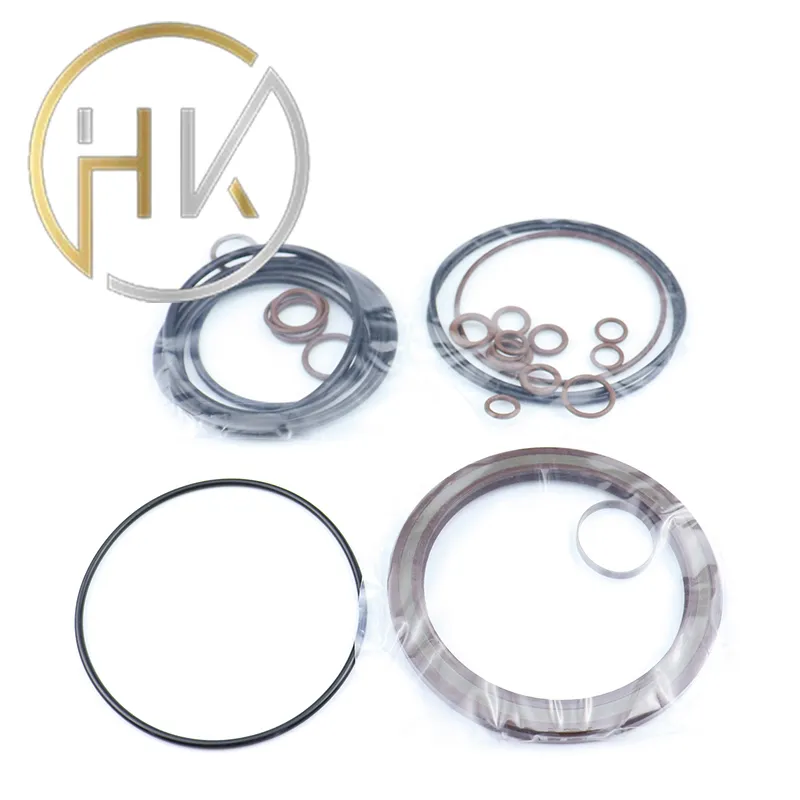

seal kit pump

Within the machinery maintenance realm, authoritative guidelines recommend a routine evaluation and replacement of pump seal kits. Manufacturer instructions often prescribe specific intervals for seal examination, depending on the operational intensity and environmental conditions. Following these guidelines ensures the pump remains in optimal working condition, minimizing the risk of unexpected failures. The authoritative voices in the industry consistently emphasize the importance of using original equipment manufacturer (OEM) parts over generic alternatives to guarantee compatibility and performance reliability. Trustworthiness in the realm of seal kit pumps demands transparency from manufacturers and sellers. It involves providing detailed specifications, performance data, and clear maintenance guides to buyers. Buyers rely on these resources to make informed decisions, ensuring the chosen seal kit meets their precise operational needs. Additionally, building trust can also be facilitated through comprehensive after-sales support and warranties that protect the consumer's investment. In summary, the seal kit pump is not merely an accessory but a cornerstone of pump efficiency and longevity. The combination of real-world experience, enhanced expertise in selection, adherence to authoritative protocol, and a focus on trustworthiness form the foundation of a successful seal kit pump strategy. By prioritizing these aspects, businesses can achieve an optimal balance of performance, reliability, and cost-efficiency in their fluid handling systems. Embracing high-quality seal kits and regular maintenance practices guarantees prolonged lifespan and uninterrupted service of pumps across various industries.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories