1 月 . 31, 2025 01:46 Back to list

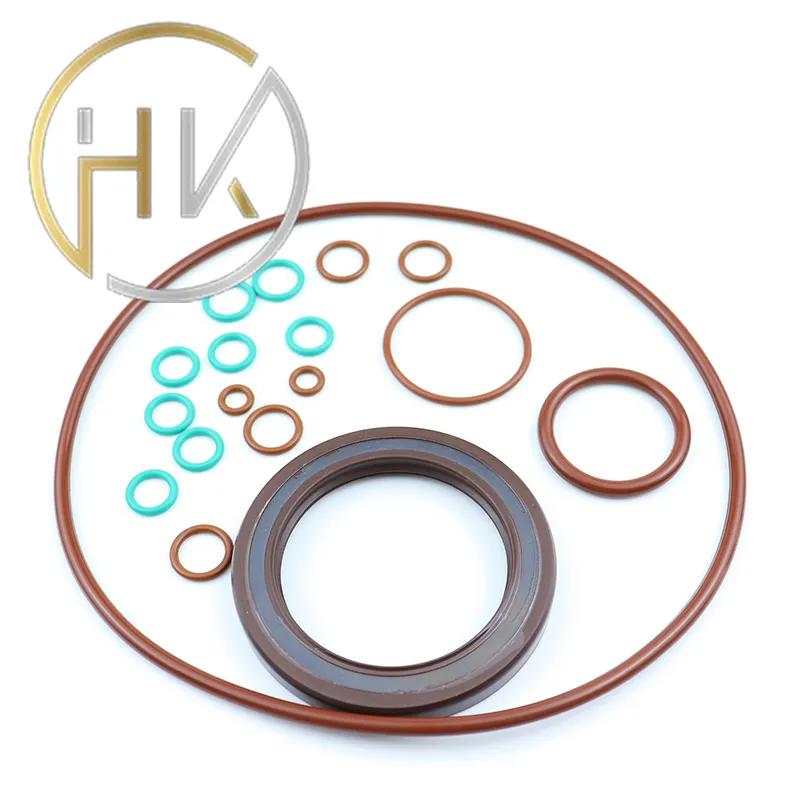

seal kit hydraulic pump

Installation and Maintenance Know-how Beyond selection, mastering the installation and maintenance of seal kits determines their efficacy and lifespan. Improper installation—a common pitfall—can lead to immediate failure. Hence, consulting the installation guidelines provided by the manufacturer or working with certified professionals can safeguard against such risks. Regular inspection and timely replacement of seal kits are equally essential, enabling your machinery to consistently operate at peak performance. Studies show that scheduled maintenance increases the service life of hydraulic systems by up to 40%. Balancing Cost with Durability and Efficiency The cost-effectiveness of seal kits doesn’t merely equate to purchasing the least expensive option. Instead, it’s about investing in quality that ensures durability and efficiency. Highly durable seal kits might demand a higher upfront investment, but they substantially lower the total cost of ownership by minimizing breakdowns and extending service intervals. Through client feedback, a consistent pattern emerges businesses that prioritize quality save significantly on long-term operational costs. Choosing a Reputable Supplier Sourcing seal kits from reputable suppliers is foundational to establishing trustworthiness and reliability in hydraulic pump operation. Engaging with suppliers who not only provide products but also share knowledge, offer detailed material safety data sheets (MSDS), and have robust after-sale support leads to enhanced operational outcomes. The industry thrives on partnerships built on reliability and transparent communication. In conclusion, choosing the correct seal kit for hydraulic pumps is a nuanced process that calls for a blend of experience, technical knowledge, and foresight. Acknowledging these elements not only maximizes the efficiency and safety of your machinery but also positions you strategically for future innovations in hydraulic technology. Transformative operational success hinges upon the often-overlooked detail—a detail as crucial as your hydraulic pump’s seal kit.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories