2 月 . 15, 2025 10:13 Back to list

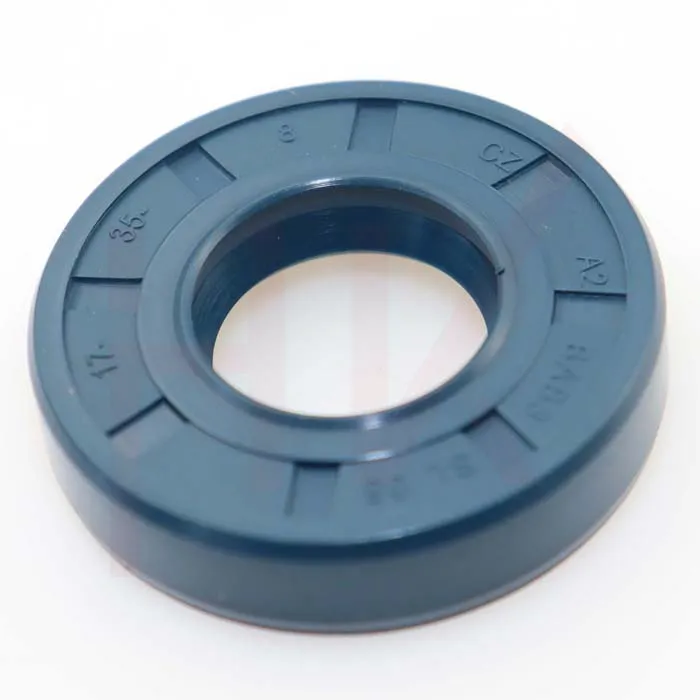

rotary shaft seal

Authoritativeness in the domain of rotary shaft seals often comes from leading manufacturers and industry-standard testing facilities that set benchmarks for performance. These entities provide certifications and ratings that ensure seals meet or exceed operational demands. Relying on products tested to these standards is a testament to a company's commitment to quality and performance assurance. Trustworthiness is an attribute best established through consistent performance and a transparent track record. Manufacturers that offer comprehensive technical support, warranty assurances, and clear documentation on installation techniques and material properties are perceived as more reliable partners. This trust extends to regular updates on new advancements in seal technology, which can preemptively address emerging industrial challenges or innovations. In conclusion, rotary shaft seals, while often overlooked, are essential to the efficient operation of mechanical systems. Their proper selection and implementation require a balanced mix of empirical experience, expert knowledge, authoritative data, and a trustworthy manufacturer partnership. By focusing on these key areas, businesses not only enhance the durability of their machinery but also ensure the highest standards of operational efficiency and minimal downtime. This symbiotic relationship between engineering foresight and practical application defines the modern approach to rotary shaft seal integration across industries.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories