2 月 . 14, 2025 03:35 Back to list

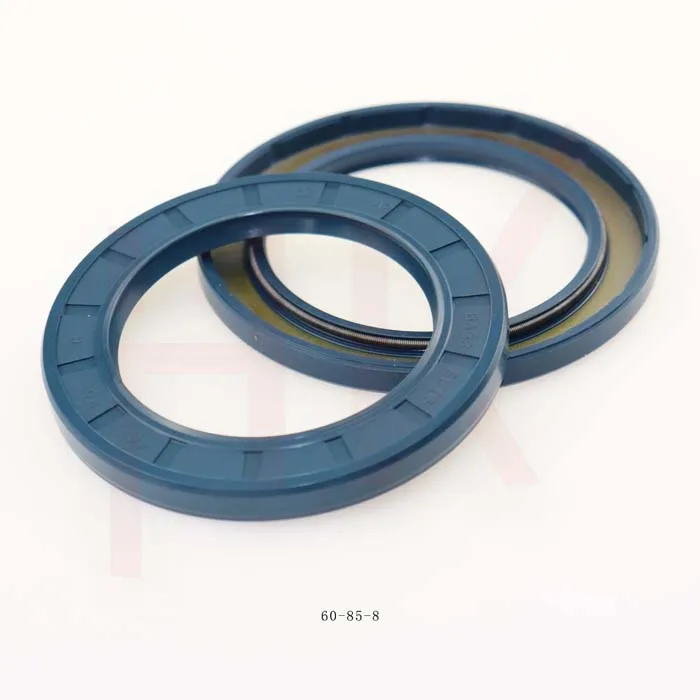

wiper seals

3. Remove the Old Wiper Seal With the cylinder opened, locate the wiper seal. Use a seal puller or a flat tool to carefully extract the old seal, taking care not to scratch or damage the surrounding surfaces. 4. Inspect and Clean Inspect the rod and surrounding areas for any signs of wear, corrosion, or damage. Clean the components thoroughly to remove any debris or contamination that could affect the new seal’s performance. 5. Install the New Seal Lightly lubricate the new wiper seal with hydraulic fluid to ease installation. Carefully position and press it into the groove, ensuring it sits flush and even. Using appropriate installation tools can help avoid damage to the seal. 6. Reassemble the Cylinder Reassemble the cylinder following your documentation. Ensure proper alignment and torque specifications are met according to the manufacturer's guidelines. 7. Test the System After reassembly, test the hydraulic cylinder under low pressure to check for leaks or additional signs of wear. Gradually increase the pressure to full operational settings, monitoring the system closely. Professional Tips - Always use OEM parts or high-quality aftermarket replacements to ensure longevity and compatibility. - Maintain a routine inspection schedule to identify potential issues before they necessitate a complete system overhaul. - Keep detailed maintenance records, as this history is invaluable for troubleshooting future issues. In achieving mastery in hydraulic maintenance tasks like wiper seal replacement, one not only ensures the machinery's optimal performance but also extends its operational life significantly. By adhering to these expert recommendations and protocols, you cultivate a practice of precision and reliability, fostering trustworthiness in every maintenance activity. This comprehensive guide serves as a testament to the expertise and authoritative standards required for such specialized work, providing an unparalleled resource for technicians worldwide.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories