2 月 . 14, 2025 03:09 Back to list

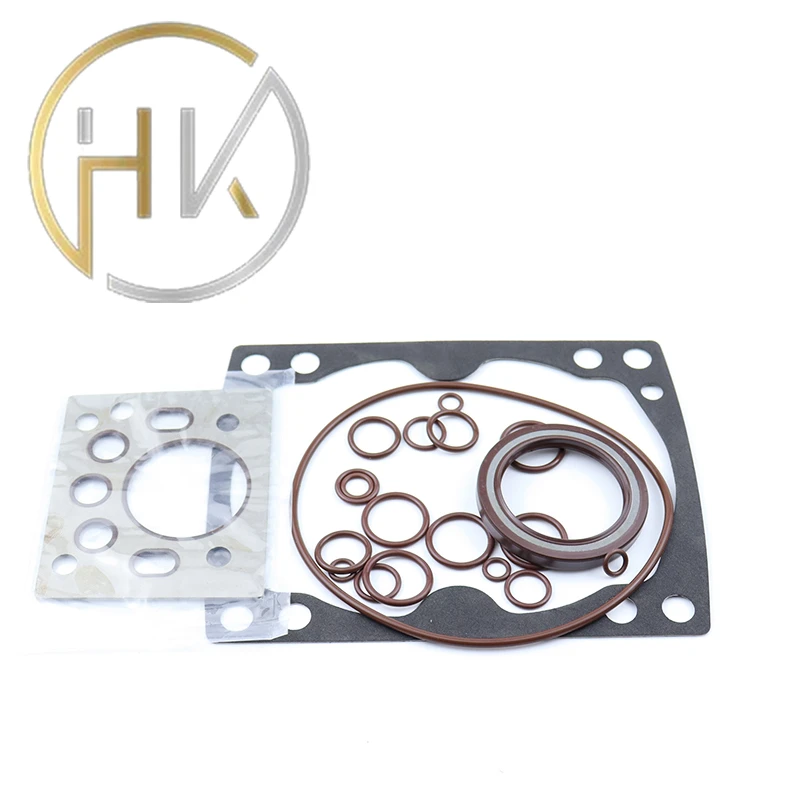

wiper seals

Authoritativeness in the realm of wiper seals also springs from empirical studies and industry standards that endorse the use of polyurethane as the material of choice due to its superior properties. Respected bodies and journals within the hydraulic and pneumatic sectors confirm that a well-installed PU wiper seal adheres to stringent operational standards, thereby ensuring optimal equipment performance and meeting or exceeding industry benchmarks. Trustworthiness arises from consistent, favorable outcomes observed in systems utilizing PU wiper seals over prolonged periods. Testimonies from industry professionals bear witness to reduced system failures, decreased maintenance costs, and improved machine uptime. The credibility of PU wiper seals is further bolstered by the warranty offered by reputable manufacturers, which often cover prolonged periods due to the reliability of the polyurethane material. The real-world application and long-term performance of PU wiper seals are vividly demonstrated in industries ranging from construction and agriculture to automotive and aerospace. Their versatility under extreme conditions, ranging from variable temperature fluctuations to heavy-duty operations, showcase their adaptability and critical role in ensuring the seamless operation of a broad spectrum of machinery. In conclusion, the PU wiper seal stands out in the product category for its combination of resistance, adaptability, and durability. For everyone from engineers to procurement officers, the promise of reduced maintenance cycles and enhanced machinery lifespan makes it a prudent investment. As technology continues to evolve, the reliance on proven, high-performance materials like polyurethane will maintain its importance in sustaining the efficiency and longevity of intricate hydraulic and pneumatic systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories