1 月 . 30, 2025 02:02 Back to list

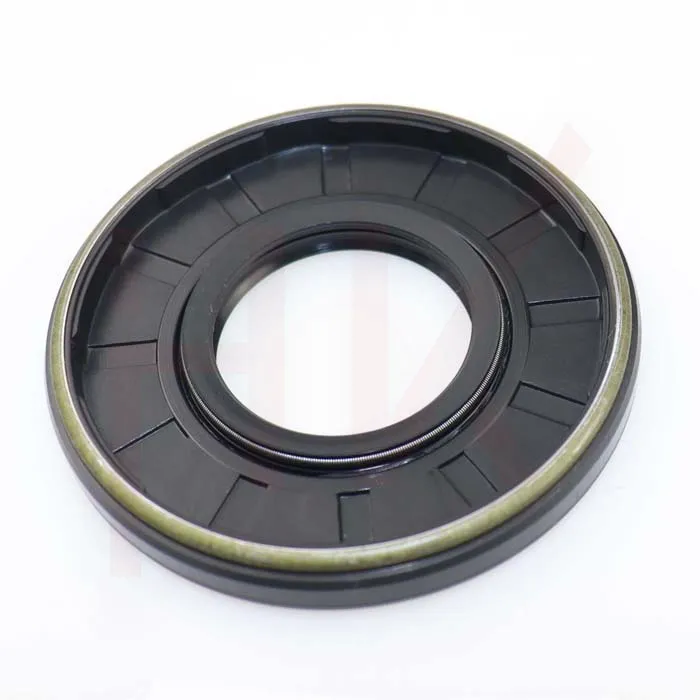

replacing wiper seal on hydraulic cylinder

4. Inspect and Clean Thoroughly inspect the rod for any signs of damage or wear. Clean all components meticulously using approved cleaning fluids to remove residues, ensuring that the new seal can function optimally. 5. Install the New Wiper Seal Gently position the new seal into the designated groove using appropriate tools, ensuring it sits flush and evenly. It's essential to use manufacturer-recommended seals to match the specific cylinder's dimensions and operational pressures. 6. Reassemble the Cylinder Reassemble the components with an emphasis on ensuring all parts are in correct alignment. Tighten fasteners to the manufacturer's specifications to maintain system integrity. 7. Test the System Once reassembled, engage the hydraulic system and monitor its operation. Observe for leaks, check the ease of movement, and ensure no contaminants breach the seal area. Consistent performance indicates a successful seal replacement. Benefits of Proper Wiper Seal Replacement Efficient wiper seal replacement substantiates itself through improved hydraulic effectiveness, reduced maintenance costs, and longer equipment lifespan. Correct installations foster cylinders that operate smoothly without contamination interruptions, thereby augmenting a company's operational efficiency and reliability. Trusting the Expertise Reliability in wiper seal replacement hinges upon utilizing experienced professionals whose technical proficiency is backed by credible and detailed procedural knowledge. Leveraging proper tools and adherence to manufacturer specifications reinforces trustworthy outcomes, protecting valuable equipment and ensuring dependable system functionality. By prioritizing expert-driven maintenance practices, businesses can cultivate environments where hydraulic systems perform impeccably, thus reinforcing trust in their operational dependability and extending the life of critical machinery investments.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories