1 月 . 29, 2025 05:55 Back to list

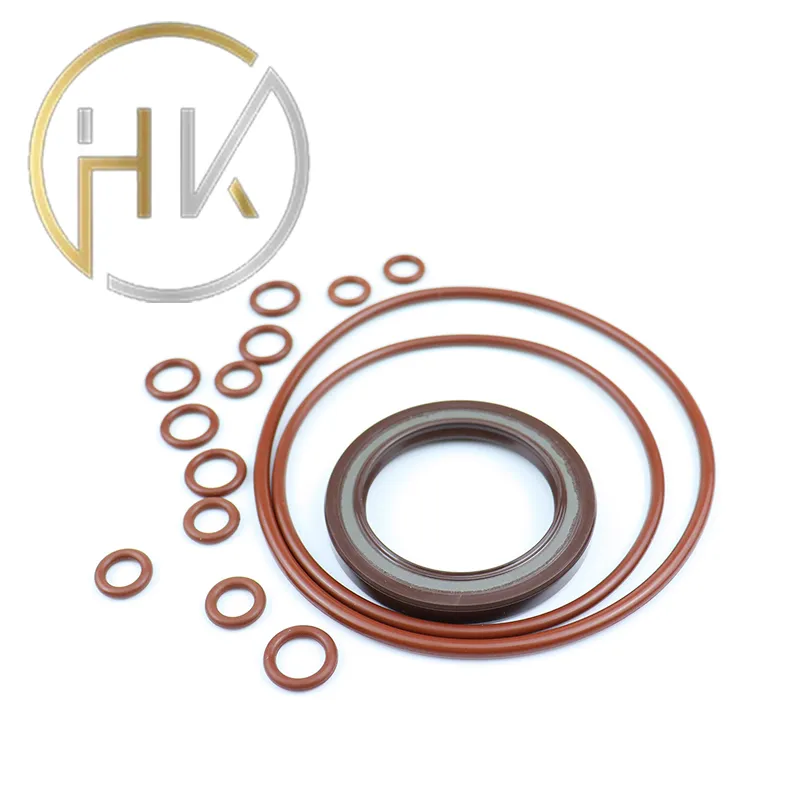

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Authoritativeness in any discussion around piston wiper rings hinges on data-driven research and field-tested results. Many industry-leading companies invest significantly in testing wiper rings under simulated real-world conditions to ensure their products can withstand the rigors of demanding environments. Scholarly articles and technical papers published by organizations such as the Society of Automotive Engineers (SAE) offer valuable insights, suggesting best practices and sharing findings from rigorous testing protocols. Such documentation confirms the piston wiper ring's role as more than just a simple mechanical component, but rather a vital player in reducing friction and promoting the engine's overall health. Trustworthiness is established through the consistent performance and reliability of piston wiper rings across multiple applications. Manufacturers that lead the industry prioritize quality assurance, implementing strict guidelines and quality checks at each production stage. This dedication to quality has earned them certifications and endorsements from respected bodies that vouch for their product's reliability and performance standards. Consumer reviews, particularly those from long-term users, further reinforce trustworthiness by providing authentic feedback that underscores the durability and efficiency of well-crafted piston wiper rings. In conclusion, the piston wiper ring serves as a testament to the intricate balance of design, material science, and engineering that underpins modern machinery. For professionals seeking to enhance engine performance, reduce maintenance costs, and achieve higher fuel efficiency, investing in quality piston wiper rings is paramount. By understanding the experience, expertise, authoritativeness, and trustworthiness surrounding this essential component, decision-makers can make informed choices that align with their operational goals and sustainability targets.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories