1 月 . 29, 2025 05:31 Back to list

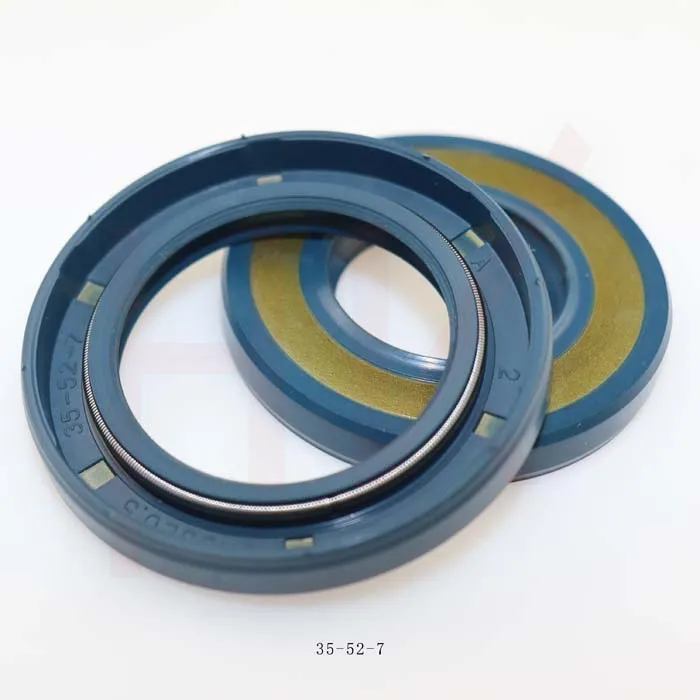

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Professionals in the field recognize the expertise involved in selecting and maintaining these components. Choosing the right oil wiper ring requires an understanding of the specific operating conditions, including temperature ranges, pressure levels, and the type of fluids involved. Manufacturers like SKF, Trelleborg, and Freudenberg-NOK provide detailed specifications and support, helping industry specialists make informed decisions to optimize their equipment's performance. Furthermore, authoritativeness in this domain is established by industry standards and rigorous testing protocols. Companies producing oil wiper rings often adhere to ISO and ASTM standards, which guarantee that these parts meet the necessary requirements for performance and safety. It’s not uncommon for such manufacturers to participate in continual research and development, staying ahead of technological advances and material science breakthroughs. Finally, trustworthiness is a critical factor for clients sourcing oil wiper rings. Trusted suppliers are those who not only provide certified and rigorously tested products but also offer comprehensive service agreements. They should demonstrate transparency regarding production methods and offer warranties that affirm their confidence in the product's durability. In summary, the world of oil wiper rings is an intersection of material science, precision engineering, and practical expertise. Those in need of these components will benefit from choosing products that demonstrate high standards of experience, expertise, authority, and trustworthiness. By giving due importance to the selection and maintenance of oil wiper rings, businesses can ensure smoother operations, longer equipment lifespan, and cost efficiencies.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories