2 月 . 20, 2025 09:37 Back to list

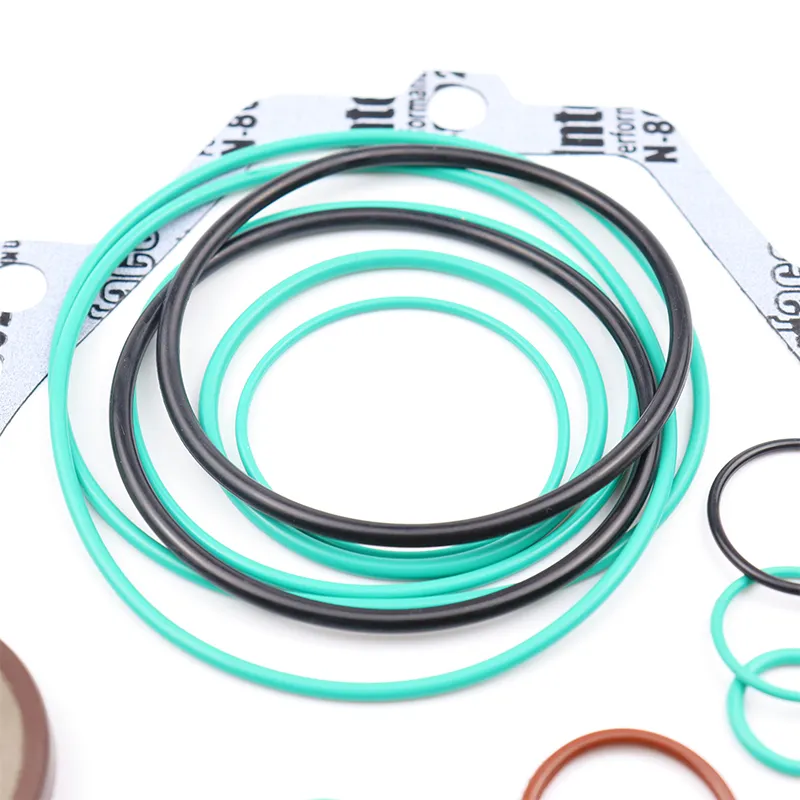

Standard High Pressure TCV Type Hydraulic Oil Seal

Adding a layer of authoritativeness, the insights from leading automotive engineers and seal manufacturers underscore the importance of kerf edges or specialized sealing lips that enhance the oil seal’s efficacy under pressure differentials. Such designs have been rigorously tested across multiple platforms, with results published in leading automotive engineering journals. These insights are not simply theoretical; they are grounded in real-world applications and have been implemented in vehicles used in extreme climates, demonstrating their universal applicability. Trustworthiness is paramount when selecting automotive components – and oil seals are no exception. Opting for seals from reputable manufacturers that meet (or exceed) industry standards like ISO and OEM specifications can make a profound difference. Such companies often provide warranties and comprehensive customer support, which adds another layer of security for the buyer. Furthermore, sourcing from well-established vendors helps ensure traceability, making it easier to address any quality concerns that may arise. In conclusion, while oil seals are only a small piece of the automotive puzzle, they play a disproportionately large role in maintaining vehicle performance and safety. A well-chosen seal contributes not only to the wheel hub's function but also drives efficiency, reduces downtime, and ultimately extends the vehicle's lifespan. It's an investment that pays multifaceted dividends, ensuring reliability on the road while optimizing cost management over the vehicle's operational lifetime. Understanding both the fundamental and intricate aspects of oil seals empowers vehicle owners to make informed decisions, girded by a mesh of experience, expertise, authoritative resources, and trustworthy sources.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories