2 月 . 20, 2025 09:14 Back to list

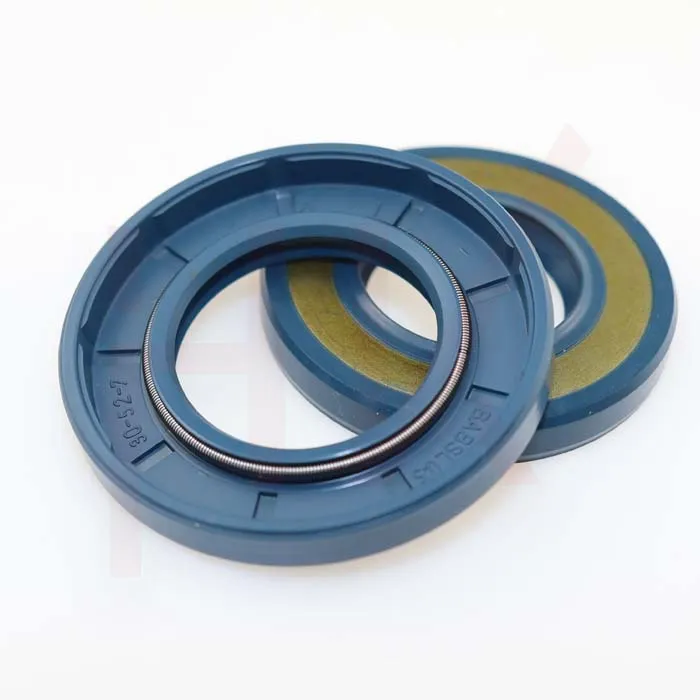

Standard High Pressure TCV Type Hydraulic Oil Seal

With a focus on environmental sustainability, the engineering of oil seal hubs has evolved to include eco-friendly designs that aim to minimize the ecological footprint of machinery operations. These designs prioritize efficiency while adhering to environmental regulations, thus enhancing the overall trustworthiness of the machinery and reassuring stakeholders of their commitment to ecological stewardship. Expertise in selecting and maintaining oil seal hubs comes from a deep understanding of the specific requirements of the machinery. Different scenarios demand particular designs and materials, depending on the pressure, temperature, and type of lubricant used. This is where the authoritative input of professionals—mechanics, engineers, and manufacturers—becomes vital. Their knowledge encompasses the nuances of seal integrity under various operational conditions, ensuring optimal performance across diverse applications. Trustworthiness extends beyond the product itself, involving the reliability and ethics of the suppliers and manufacturers. Reputable brands that adhere to the highest standards of quality control and production ethics are considered more reliable. Checking certifications and customer testimonials can be beneficial in choosing a supplier who prioritizes performance, safety, and sustainability. In conclusion, the oil seal hub is more than a simple component; it is a vital part of the machinery ecosystem. It upholds the standards of efficiency, safety, and environmental responsibility. Through cutting-edge design, superior materials, and expert maintenance, oil seal hubs ensure that vehicles and heavy machinery continue to perform at their best, negating the risk of unforeseen breakdowns and costly repairs. With its blend of tradition and innovation, the oil seal hub stands as a testament to the seamless integration of trustworthiness, authority, and expertise in mechanical engineering.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories