1 月 . 26, 2025 07:36 Back to list

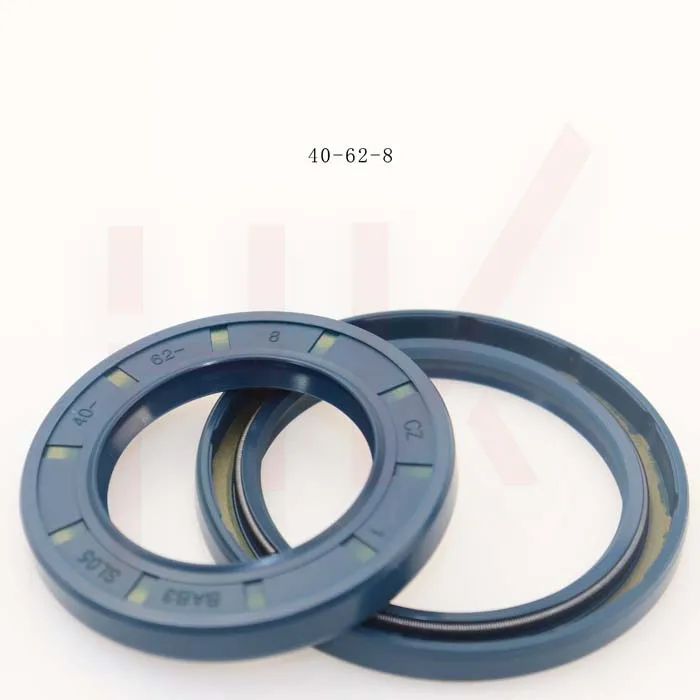

Standard High Pressure TCV Type Hydraulic Oil Seal

Authority in the field dictates that proper installation and regular inspection form the bedrock of maintaining the effectiveness of oil seal wheel hubs. Improper installation, such as insufficient seating or damage from over-pressurization, can lead to leaks and subsequent damage to other vehicle components. Therefore, adopting a systematic approach during installation—cleaning the area thoroughly, using appropriate tools, and following manufacturer guidelines—is non-negotiable. Engaging with specialists for installation and maintenance significantly reduces the risk of failure and extends the operational lifespan of the hub assembly. Trustworthiness often correlates to consistent performance and minimal need for replacement. Routine checks are paramount; even the best seals may wear over time due to heat, mechanical stress, or exposure to harsh elements. Detecting early signs of seal failure, such as visible lubricant leaks or audible noise from the wheels, can prevent extensive damage. Documenting these maintenance endeavors not only preserves the integrity of the vehicle but also supports trustworthiness by ensuring that an objective record validated by a certified professional is kept. In summary, maintaining a vehicle’s oil seal wheel hubs with astute knowledge and vigilant care is indispensable in achieving peak vehicular performance. Their nuanced role in protecting wheel bearings and maintaining lubrication underscores the importance of expert selection, professional maintenance, and strategic inspection. By integrating high-standard products with comprehensive care protocols, vehicle upkeep transforms from a menial task into a testament of precision, reliability, and craft. For automotive professionals and enthusiasts alike, mastering the dynamics of oil seal wheel hubs is fundamental to an enlightened understanding of vehicular mechanics and operational excellence.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories