1 月 . 26, 2025 07:14 Back to list

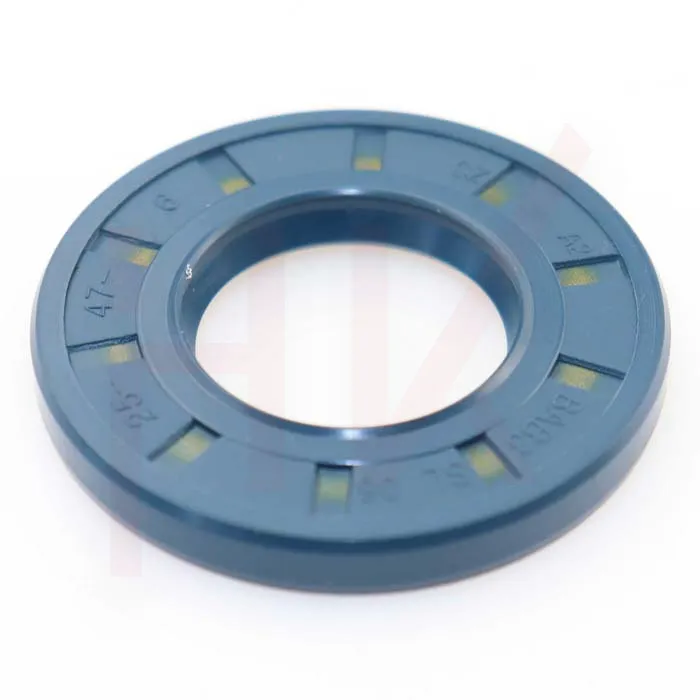

Standard High Pressure TCV Type Hydraulic Oil Seal

A genuine experience shared by industry veterans highlights the significance of regular monitoring and maintenance of oil seal hubs. Routine inspections can preemptively identify wear and tear or potential seal failure, allowing for timely interventions. Professionals advocate for incorporating predictive maintenance technologies, such as IoT sensors and real-time monitoring systems, which alert to changes in pressure and temperature that might indicate a seal is approaching its threshold. Advances in the manufacture and design of oil seal hubs herald exciting developments. With the integration of new materials and technologies, modern oil seal hubs are evolving to meet the dynamic needs of future-proof industries. Innovations like self-lubricating seals and enhanced sealing lip designs offer superior performance, accommodating higher speeds and more aggressive environments. For stakeholders involved in heavy-duty machinery, understanding the nuances of oil seal hubs isn't merely beneficial but essential. By leveraging expertise, adopting cutting-edge technologies, and prioritizing high-quality, reliable components, businesses can ensure seamless operations, minimize unscheduled downtimes, and extend the life span of their equipment. In summary, oil seal hubs are not just minor components of a machine; they are key to maintaining machinery integrity and performance. Drawing from extensive professional experience, industry knowledge, and a commitment to utilizing trustworthy products, the optimization of these seals can lead to improved efficiency, enhanced reliability, and a competitive edge in the marketplace. As industries continue to evolve, so too will the technologies behind oil seal hubs, driving a future where machinery operates longer, safer, and more effectively than ever before.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories