1 月 . 19, 2025 04:22 Back to list

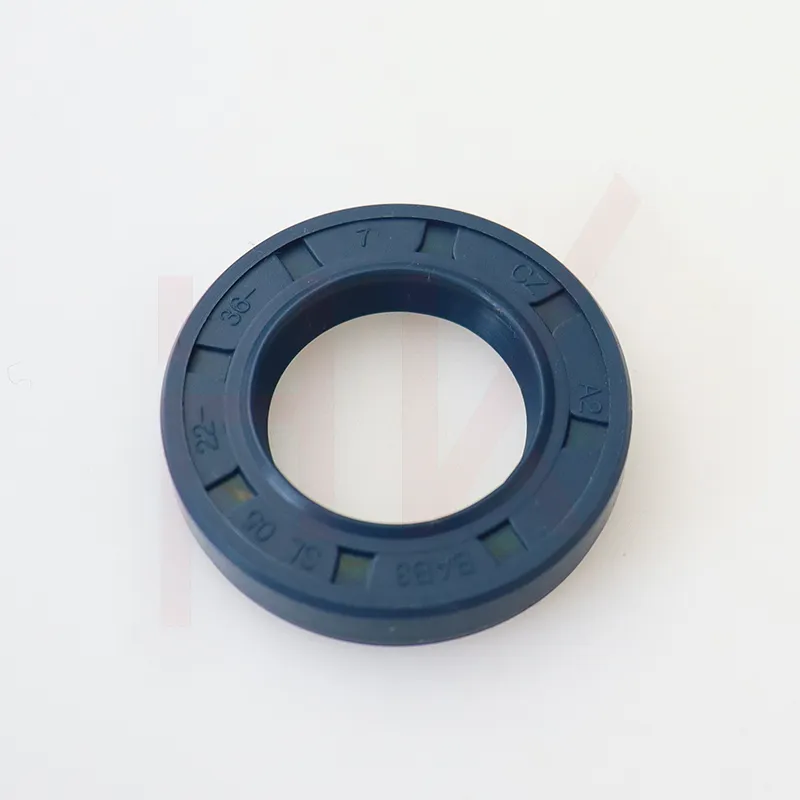

170×190×13 Tcv Oil Seal High Pressure Oil Seal Hydraulic Pump Seal

Trustworthiness in product quality is further affirmed through rigorous testing processes conducted by manufacturers. This includes pressure testing, dynamic and static sealing performance, and material compatibility tests. These evaluations ensure that the oil seals not only meet industry standards but exceed them, offering extended service life and enhanced protection for machinery components. Customer reviews and testimonials are invaluable in assessing the real-world performance of oil seals. Many users report significant reductions in maintenance downtime and cost savings attributable to the enhanced sealing capabilities and wear resistance offered by high-quality oil seals. This feedback reinforces the trust users can place in these components, presenting them as a wise investment in machinery maintenance and efficiency. In conclusion, the role of oil seals for rotating shafts extends beyond simple containment of lubricants. Their importance lies in protecting machinery by maintaining optimal operating conditions, thus ensuring extended equipment life and performance. As machinery becomes more advanced and the demands placed on these components increase, the importance of choosing the right oil seal continues to grow. By focusing on materials, fit, and compliance with industry standards, users can ensure effective and reliable sealing solutions for their specific applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories