3 月 . 05, 2025 00:56 Back to list

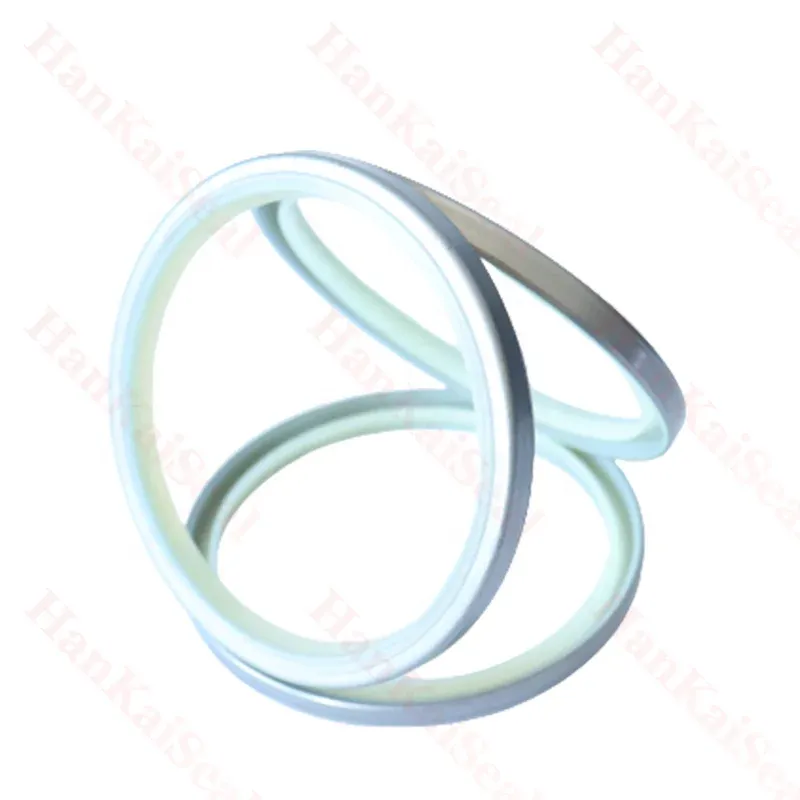

metal wiper seal

In the realm of technological innovation, the development of metal wiper seals has not stagnated. Researchers and engineers are continually testing new materials and design techniques to enhance seal performance further. The integration of cutting-edge technologies, such as laser-guided manufacturing processes and advanced coating techniques, is pushing the envelope, resulting in seals that offer even greater precision and resilience. Moreover, sustainability considerations are increasingly influencing the production of metal wiper seals. Eco-friendly manufacturing processes and the use of recyclable materials are becoming standard practices. This shift not only addresses environmental concerns but also aligns with global trends towards more responsible industrial operations. Market leaders in the production of metal wiper seals are keenly aware of the importance of staying ahead of the curve. They invest in research and development to create seals that meet and exceed industry standards, often collaborating with clients to develop custom solutions tailored to unique operational challenges. This partnership approach not only fosters innovation but also enhances the overall trust between seal manufacturers and their clientele. Ultimately, the choice and implementation of metal wiper seals can have a significant impact on machinery efficiency, operational reliability, and cost-effectiveness. By prioritizing quality, expertise, and sustainability, industries can ensure their machinery operates at peak performance, contributing to overall business success. Exploring the latest developments and trends in metal wiper seal technology is an ongoing process, one that holds the promise of even greater advancements in the industrial sector. As the demand for high-performing machinery continues to grow, the role of metal wiper seals will remain indispensable. Their contribution to protecting and enhancing equipment underscores the importance of investing in reliable, expertly designed sealing solutions, a decision that ultimately bolsters the longevity and efficiency of crucial industrial operations.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories