1 月 . 15, 2025 09:28 Back to list

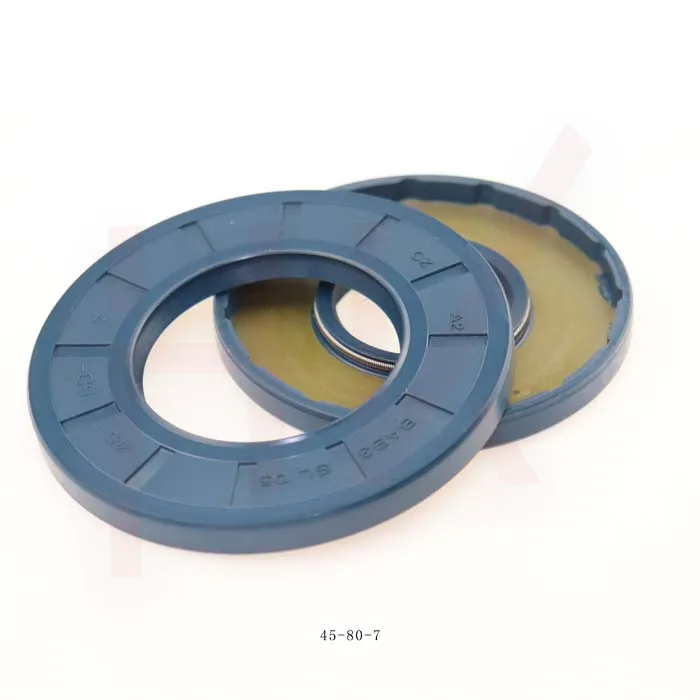

metal oil seal

The authority of metal oil seals in the market is reinforced by decades of trusted use and continuous innovation. Manufacturers strategically design these seals to cater to a variety of uses, from heavy-duty industrial equipment to compact automotive engines. Through rigorous testing and feedback from industry veterans, the engineering behind these components is continuously refined, ensuring reliability and performance. Endorsements from industry leaders only bolster their reputation, further establishing their trustworthiness. Moreover, the environmental aspect of metal oil seals cannot be overlooked. As industries worldwide push towards sustainability, the longevity and efficiency provided by these seals contribute significantly to waste reduction. By minimizing oil leakage and extending service intervals, they aid in achieving eco-friendly operations, aligning with global sustainability goals. In conclusion, metal oil seals represent a confluence of innovation and functionality. Their ability to perform under challenging conditions with minimal maintenance makes them indispensable in various industries. As more stakeholders in automotive and industrial sectors seek reliable solutions, the trust placed in metal oil seals continues to rise, driven by their proven expertise and authoritative presence in the field. If you're considering an upgrade or facing sealing challenges, exploring the advantages of metal oil seals could indeed be a game-changer for your operations.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories