2 月 . 13, 2025 23:39 Back to list

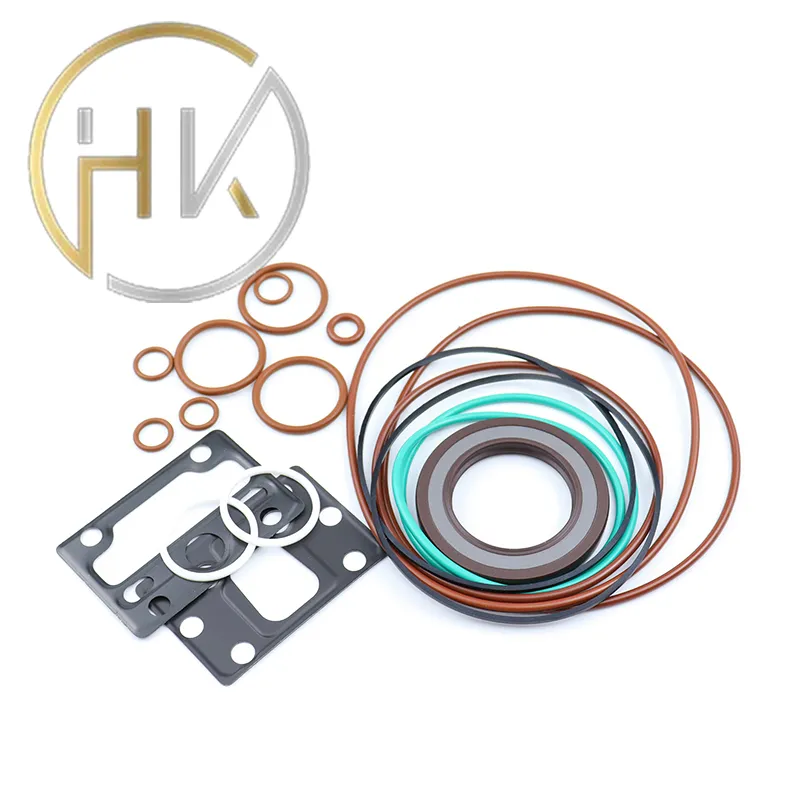

metal clad wiper seals

In terms of authoritativeness, metal clad wiper seals benefit from a wealth of research and development within engineering domains. Manufacturers often collaborate with technical experts to innovate in seal design and materials, ensuring they exceed industry standards. These collaborations result in seals that uphold rigorous operational benchmarks, offering users peace of mind in critical applications. Additionally, regulatory compliance and standardization are keystones in the production of metal clad wiper seals, providing a standardized measure of performance and safety. Trustworthiness in metal clad wiper seals is built upon a foundation of quality assurance and customer support. Reputable vendors support their products with robust warranties, detailed installation guides, and access to technical support. This commitment to customer success extends to providing comprehensive product documentation, ensuring users can optimize the performance and longevity of their seals. Moreover, real-world case studies underscore the efficacy of metal clad wiper seals in enhancing machine reliability and minimizing downtime. For instance, in the aerospace industry, the application of these seals has been instrumental in maintaining hydraulic system integrity under extreme conditions. Similarly, in the oil and gas sector, metal clad wiper seals serve as a bulwark against corrosive elements, safeguarding expensive equipment from premature deterioration. In summary, metal clad wiper seals represent a cornerstone of maintenance strategy in demanding engineering environments. Through steadfast durability, precise engineering, and a commitment to quality, these seals offer unparalleled protection and efficiency. By ensuring optimal selection, installation, and maintenance, engineers can significantly extend machinery lifespan, minimize maintenance costs, and bolster operational reliability. Each application of metal clad wiper seals stands as a testament to the innovation and expertise that define modern industrial engineering.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories