6 月 . 10, 2025 16:09 Back to list

Metal Wiper Seal Manufacturer High-Performance Metal Clad Wiper Seals & Oil Seals

- Market Overview & Introduction to Metal Wiper Seal

- Technical Advantages of Metal Clad Wiper Seals

- Industry Demand and Data Insights

- Comprehensive Manufacturer Comparison

- Custom Solutions for Diverse Applications

- Application Case Studies

- Conclusion: The Future of Metal Wiper Seal Technology

(metal wiper seal)

Market Overview & Introduction to Metal Wiper Seal

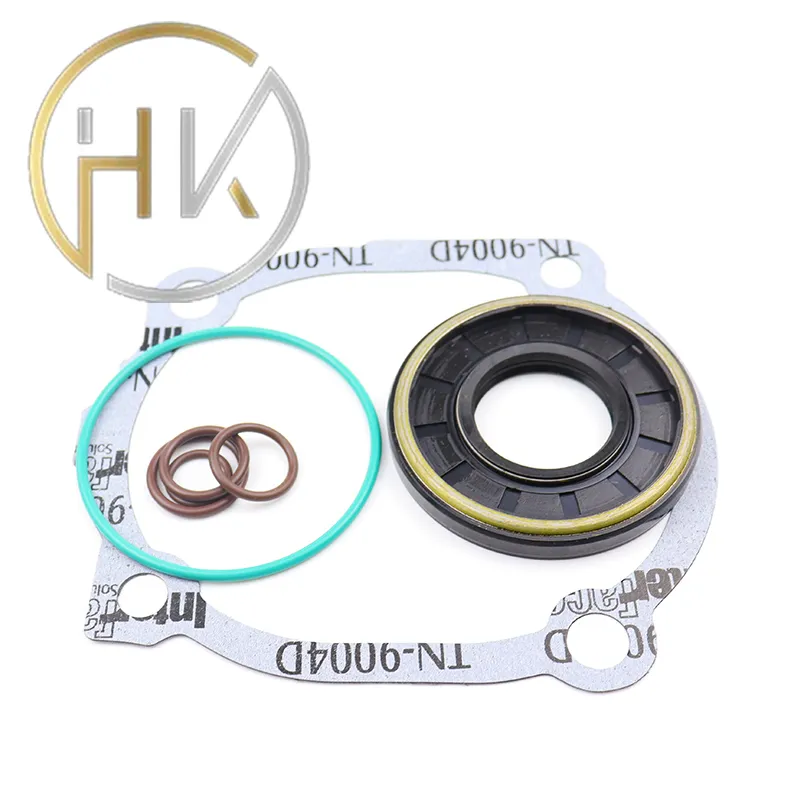

Metal wiper seal represents an integral component within modern hydraulic and pneumatic systems, ensuring peak system efficiency and extended operational longevity. Characterized by a hybrid structure, metal wiper seal

s blend the resilience of metal exteriors with precise sealing materials, such as nitrile or PTFE, designed to keep contaminants out of critical assemblies. This first line of defense is crucial: according to a 2023 European Fluid Power Association report, particle contamination accounts for up to 75% of hydraulic failures globally, highlighting the absolute necessity of advanced sealing technology.

Across diverse sectors, from heavy industrial machinery and transportation equipment to precision robotics, the adoption of metal clad wiper seals has surged by nearly 18% over the last five years. Such growth is propelled by the need for reliable operation in hostile environments, where ordinary polymer seals prove inadequate. The metal oil seal format further advances this protection, leveraging superior wear resistance and dimensional stability, thus outperforming conventional alternatives in durability tests.

Technical Advantages of Metal Clad Wiper Seals

At the cutting edge of sealing technology, metal clad wiper seals deliver a combination of mechanical strength and sealing precision. Their metallic shell shields against abrasive debris, while the engineered lip guarantees consistent exclusion of moisture and foreign particles. Unlike fully elastomeric wipers, the metal-clad design withstands high pressure and dynamic movement.

Laboratory tests demonstrate that properly specified metal wiper seals cut contaminant ingress by up to 40% beyond standard rubber equivalents. This translates directly into reduced downtime and maintenance frequency—both essential metrics in mission-critical industries. The use of high-performance alloys, such as stainless steel or zinc-plated brass, further enhances corrosion resistance, extending service intervals even in applications involving aggressive chemicals or extreme temperatures (ranging from –40°C to +200°C).

Industry Demand and Data Insights

The global market value for metal wiper seals is set to reach $1.5 billion by 2026, registering a compound annual growth rate (CAGR) of 6.7%. This robust expansion is shaped by several factors: the intensification of automation, higher performance demands in off-road vehicles, and greater awareness of maintenance cost reduction.

Innovation within metal oil seal designs has allowed reduced installation widths without sacrificing performance. For instance, sealing companies report that advanced manufacturing processes achieve tolerances as close as ±0.01mm, ensuring compatibility with custom and existing housings. Furthermore, end-user surveys across North America and Europe cite a 23% reduction in unplanned maintenance thanks to upgrades from traditional rubber wipers to metal clad options, underscoring their tangible economic benefit.

Comprehensive Manufacturer Comparison

Selecting the optimal supplier is essential for maximizing system reliability. Several leading global manufacturers offer distinctive approaches and proprietary metal wiper seal solutions. The following table compares four major vendors based on critical performance parameters:

| Manufacturer | Max Pressure (bar) |

Operating Temp. (°C) |

Lead Time (weeks) |

Core Advantage |

|---|---|---|---|---|

| SealTech Global | 350 | -40 to +180 | 5 | Ultra-fine tolerances, rapid prototyping |

| HydroSeal Corp. | 310 | -30 to +200 | 7 | Chemically enhanced metal coating |

| Olio Precision | 300 | -35 to +160 | 4 | Low-friction composite lips |

| MetallSeal Systems | 360 | -40 to +230 | 8 | Wide diameter customization |

Across key criteria, MetallSeal Systems offers the broadest temperature range and diameter spectrum, while SealTech Global stands out for lead time and prototyping. End-users should factor in not only product performance, but also supply chain responsiveness when specifying metal clad wiper seals for precision engineering projects.

Custom Solutions for Diverse Applications

Modern engineering projects increasingly require customized sealing answers. Leading manufacturers partner with clients from the conceptual stage, offering advanced simulation and design optimization services. Custom metal wiper seal configurations may include multi-lip geometries, laser-etched identification, and specialty alloy selections for niche industries.

For example, the renewable energy sector, particularly wind turbine OEMs, demand seals that manage high axial loads during harsh weather. In contrast, pharmaceutical processors prioritize food-grade compatibility and ultra-smooth surface finishes for easy sanitation. Customization extends to packaging and kitting solutions: some suppliers provide rapid-turnaround prototypes, custom branding, or integrated wear monitoring sensors, supporting both operational uptime and regulatory compliance.

Application Case Studies

Real-world deployments of metal wiper seals illustrate their measurable advantages. In 2022, a mining equipment provider reported a 28% drop in system failures after retrofitting fleets with metal clad seals, largely due to resilient performance under abrasive mud ingress. Similarly, a European railcar maintenance operator documented a 15% extension in wheelset service intervals after upgrading to metal oil seals designed for high frequency vibration environments.

In the field of injection molding, manufacturers have adopted metal wiper seal elements to prevent polymer buildup and costly scrap. Data collected across a sample of 50 facilities indicate a return on investment within 12 months following seal upgrades, driven by decreased machine downtime and improved batch consistency. These outcomes reinforce the vital role of carefully specified metal clad wiper seals in mission-critical industries.

Conclusion: The Future of Metal Wiper Seal Technology

The ongoing advancement of metal wiper seal technology continues to raise expectations for reliability, contamination control, and adaptability. Demand for tailored solutions continues to climb as industries pursue greater automation and harsher working environments. Looking ahead, the integration of smart sensors, predictive maintenance analytics, and advanced nano-coatings is set to revolutionize the value proposition of metal clad wiper seals.

As manufacturers and end-users align on higher performance standards, investment in innovation will shape the next generation of sealing products. Companies leveraging robust supplier relationships and technical expertise will secure enduring returns, ensuring their hydraulic systems remain protected and efficient in the face of mounting operational challenges.

(metal wiper seal)

FAQS on metal wiper seal

Q: What is a metal wiper seal?

A: A metal wiper seal is a sealing component designed to remove contaminants from moving surfaces while offering high durability. It typically features a metal case for structural strength. These seals are commonly used in hydraulic and pneumatic applications.Q: How does a metal clad wiper seal differ from a standard wiper seal?

A: A metal clad wiper seal incorporates a metal casing that enhances its rigidity and installation stability. This differentiates it from standard wiper seals, which may be made purely of elastomeric materials. Metal clad variants are ideal for demanding environments.Q: Where are metal wiper seals typically used?

A: Metal wiper seals are mainly used in industries like automotive, hydraulic machinery, and heavy equipment. They protect systems from dust, dirt, and moisture. Their robust construction makes them suitable for high-pressure environments.Q: What is the purpose of a metal oil seal?

A: A metal oil seal is designed to retain lubricants and exclude contaminants in rotating or reciprocating machinery. The metal outer shell provides extra strength and precise fit. This helps maintain long-term system efficiency.Q: Are metal wiper seals reusable or serviceable?

A: Metal wiper seals are generally not reusable after removal, as deformation can affect their sealing performance. It is recommended to replace them with new seals during maintenance. Proper installation ensures maximum lifespan and performance.-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories