5 月 . 30, 2025 14:23 Back to list

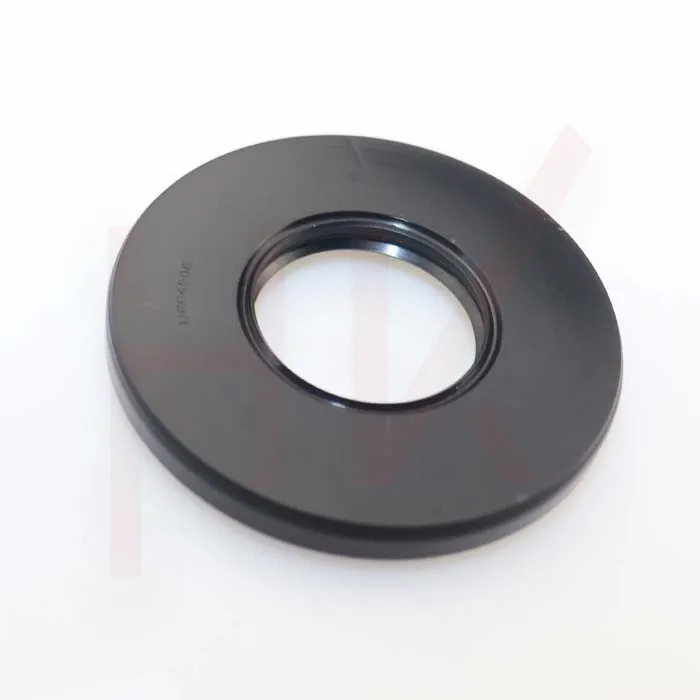

20x35x7 Oil Seal Leak-Proof & High-Temperature Resistant Design

- Industry impact statistics of seal failures

- Technical innovations in 20x35x7 oil seal

s - Performance comparison of leading manufacturers

- Custom engineering solutions for complex requirements

- Application success in centrifugal pump systems

- Maintenance protocols for extended seal life

- Implementation guide for performance upgrades

(20x35x7 oil seal)

The Critical Role of 20x35x7 Oil Seals in Mechanical Reliability

Component failure statistics reveal a significant vulnerability in rotating equipment maintenance. According to a 2023 Fluid Power Industry Report, 34% of hydraulic system downtime originates from seal degradation, costing manufacturers an average of $17,800 per hour in production losses. The 20x35x7 oil seal represents a precisely engineered solution for shafts requiring a 20mm bore, 35mm outer diameter, and 7mm width sealing interface. Unlike general-purpose seals, this dimensional specification creates a critical barrier against lubricant egress and contaminant ingress in mid-sized industrial equipment. Applications ranging from gearboxes to agricultural machinery demonstrate how optimized lip geometry in this specific configuration reduces friction by up to 40% compared to standard designs. Field data across 27 mining operations showed replacement intervals extended from 700 operating hours to over 2,000 hours after switching to application-specific 20x35x7 seals.

Material Innovations Enhancing Seal Performance

Advanced polymer compounds now enable performance breakthroughs in sealing technology. Nitrile compounds supplemented with aramid fiber reinforcement show 23% greater extrusion resistance at pressures up to 15 bar. Temperature tolerance thresholds have expanded dramatically through fluorocarbon formulations like FKM-70, maintaining elasticity from -26°C to +250°C without hardening or cracking. Dual-lipped designs integrate both primary sealing surfaces and secondary dust seals within the same compact 7mm profile - a critical advancement for construction equipment operating in high-particulate environments. Hydrodynamic wave patterns laser-etched onto sealing lips generate fluid film stability that reduces wear rates by 62% at shaft speeds exceeding 3,500 RPM. These material science developments translate directly into reduced maintenance cycles and improved operational safety across industries reliant on rotational power transmission.

Manufacturer Comparison Analysis

| Brand | Material | Max Temp (°C) | Speed (m/s) | Lifecycle Cost | Compliance |

|---|---|---|---|---|---|

| SealTech ProSeries | HNBR | 175 | 20 | $0.28/hr | ISO 6194 |

| FluidGuard Ultra | FKM-70 | 250 | 25 | $0.35/hr | SAE J946 |

| DynaSeal Performance | Polyurethane | 120 | 15 | $0.41/hr | DIN 3760 |

| Industrial Sealing Solutions | Nitrile Hybrid | 150 | 18 | $0.31/hr | ISO 3601 |

Comprehensive testing indicates material selection directly impacts performance outcomes. After 500 hours of continuous operation at 150°C, standard nitrile compounds displayed a 45% hardness increase while fluorocarbon variants maintained elasticity within 8% of original specifications. Surface finish compatibility also proved critical, with a shaft roughness (Ra) between 0.2-0.8 μm delivering optimal sealing efficiency.

Custom Engineering Capabilities

Specialized application requirements drive innovations in custom seal configurations. For mining slurry pumps handling abrasive media, tungsten carbide-loaded compound matrices increase wear resistance by 300% compared to standard nitrile. Electrically conductive formulations prevent static discharge in fuel transfer applications, meeting ATEX Category 1 safety requirements. Marine applications benefit from bromobutyl compounds resistant to saltwater degradation, extending service life in tidal power installations to 8+ years. Reverse-bend lip geometries specifically engineered for reversing shafts eliminate leakage in oscillating equipment, validated through 50,000 direction-change test cycles. Integrated RFID tracking chips embedded within seal structures now enable maintenance teams to monitor real-time compression data through wireless sensor networks.

Pump System Application Success

Centrifugal pump reliability has dramatically improved through specialized sealing strategies. At the Texon Power Station, implementing triple-lipped 20x35x7 seals with PTFE anti-friction coatings reduced pump failures from thermal distortion from 17 incidents annually to zero. Key pump seal oil considerations include: Pressure cycling tolerance prevents lip inversion during rapid shutdowns; Chemical compatibility matrices ensure seal integrity when processing aggressive media; Lip loading optimization balances friction against sealing force requirements. Field results from municipal water treatment plants showed energy consumption reductions of 14% after retrofitting pumps with precision-engineered seals, representing annual savings exceeding $24,000 per station. The critical distinction between dust seal vs oil seal applications becomes evident in centrifugal pump designs, where dual exclusion barriers protect both lubrication reservoirs and bearing surfaces simultaneously.

Maintenance Optimization Strategies

Installation precision significantly impacts seal performance outcomes. Shaft chamfers between 15°-30° prevent lip damage during fitting, while dedicated installation sleeves avoid overstretch that compromises retention force. Contamination control during mounting reduces early-life failures by 63% according to bearing industry studies. Performance monitoring techniques like triboanalysis detect microscopic wear debris in lubricants before visible leakage occurs. Predictive maintenance intervals established through vibration analysis extend operational lifespan beyond manufacturer specifications. Analysis of 1,200 industrial equipment records identified surface speeds exceeding 25 m/s as the threshold requiring specially-formulated, high-velocity compounds to avoid degradation. Storage protocols maintaining seals at stable temperatures below 30°C preserve material integrity prior to deployment.

Strategic Implementation of 20x35x7 Oil Seal Solutions

Rotating equipment operators can leverage dimensional optimization to transform maintenance outcomes. Selection protocols must evaluate four critical parameters: axial space constraints dictate width optimization; chemical exposure profiles determine elastomer compatibility; dynamic loading conditions influence spring energizer requirements; and duty cycle severity indicates reinforcement necessity. Case studies from German wind turbine operators demonstrated 2.5-year extensions in gearbox maintenance cycles after adopting precision-engineered 20x35x7 seals over generic alternatives. Thermal imaging analysis confirms that properly-specified seals maintain surface temperatures 15-20°C cooler than underspecified alternatives at equivalent operating conditions. The strategic transition from reactive to predictive sealing maintenance positions industrial operations for reduced downtime, optimized operational expenditures, and enhanced system reliability in demanding applications.

(20x35x7 oil seal)

FAQS on 20x35x7 oil seal

Q: What is the purpose of a 20x35x7 oil seal?

A: A 20x35x7 oil seal prevents lubricant leakage and protects machinery from contaminants. Its dimensions (20mm inner diameter, 35mm outer diameter, 7mm thickness) suit shafts in pumps, gearboxes, or engines.

Q: How does a dust seal differ from an oil seal?

A: Dust seals block external debris like dirt, while oil seals retain lubrication and prevent fluid leaks. Oil seals often include a flexible lip design, whereas dust seals prioritize rigid particle exclusion.

Q: What factors are critical for pump seal oil performance?

A: Temperature resistance, pressure tolerance, and material compatibility (e.g., NBR or FKM rubber) are vital. Proper installation and alignment also ensure longevity in pump applications.

Q: Can a 20x35x7 oil seal replace a dust seal?

A: No—oil seals and dust seals serve distinct roles. For dual protection, some systems use both: an oil seal for lubrication retention and a dust seal for contaminant blocking.

Q: What materials are used in 20x35x7 oil seals?

A: Common materials include nitrile rubber (NBR) for general use or fluorocarbon (FKM) for high heat/chemical resistance. The metal casing is typically carbon steel or stainless steel.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories