2 月 . 12, 2025 16:20 Back to list

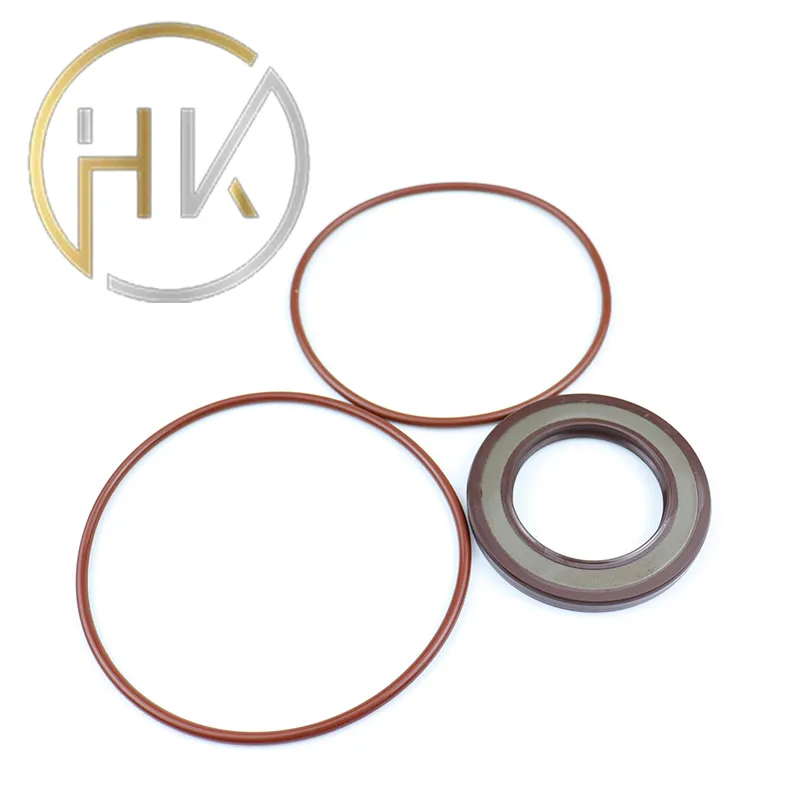

Standard High Pressure TCV Type Hydraulic Oil Seal

Authoritativeness in seal kit selection is reinforced by choosing products from reputable manufacturers. These entities invest in stringent testing and adhere to international quality standards, ensuring their products perform reliably under demanding conditions. Brands with ISO certification or strong reputations in the hydraulic industry often offer more durable and efficient seal kits. Trustworthiness of information regarding seal kits can be ascertained by consulting with industry experts, reading customer reviews, and leveraging technical forums where professionals discuss their experiences. These sources provide real-world insights into seal kits' performance, helping to avoid costly mistakes. Moreover, innovative digital tools and platforms are increasingly available, aiding the selection process. Some manufacturers offer online databases that allow you to input machinery specifications to recommend appropriate seal kits by size, thereby enhancing precision and minimizing error. Regular maintenance schedules and periodic inspections of hydraulic systems should not be overlooked. Consistent performance checks allow for early detection of seal wear and potential leaks, thus extending the lifespan of hydraulic components and avoiding unplanned downtime. In leading the field with sound experience, specialized knowledge, and proven authority, selecting hydraulic cylinder seal kits by size is less complex and prone to error. It ensures that hydraulic systems operate efficiently, thereby optimizing productivity and extending equipment lifespan. Prioritize learning from credible sources and professionals and utilize technological advancements to their fullest to make informed decisions.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories