2 月 . 12, 2025 15:39 Back to list

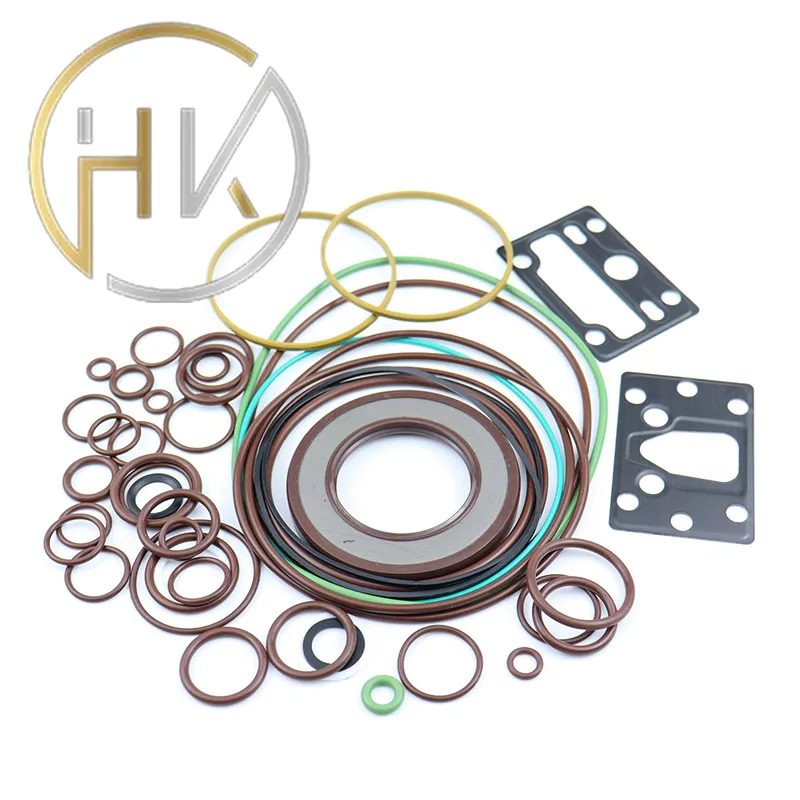

Standard High Pressure TCV Type Hydraulic Oil Seal

Lastly, wear rings or guide rings are used to absorb side loads and ensure the rod and piston assembly remains accurately aligned within the cylinder bore. This precision is critical in preventing uneven wear of the seals and ensuring the efficiency of the cylinder. For those with a deep understanding of hydraulic systems, selecting the appropriate seal kit means taking into account the specific requirements of the machinery, including operating pressure, temperature ranges, and the type of hydraulic fluid used. Expertise in assessing these factors allows for choosing a kit that not only fits perfectly but also enhances system reliability and performance. Professional technicians and engineers recognize that beyond just acquiring a seal kit, proper installation is key to maximizing the cylinder’s effectiveness. Procedures must be followed meticulously, and specifications should be adhered to remove old seals and replace them without damaging the components. This attention to detail underscores the expertise required to ensure seamless operation. Using manufacturer-recommended kits and parts also underscores the commitment to quality and trust. Authorized parts ensure compatibility and come with the assurance of performance standards that are critical to maintaining the hydraulic system's reputation and reliability. In conclusion, a 4-inch hydraulic cylinder seal kit is a small yet pivotal component for ensuring that heavy hydraulic machinery performs at its best. It underscores the importance of expertise in selecting and maintaining these systems, offering assurances of durability, efficiency, and reliability. Those invested in maintaining top-tier performance in industrial applications recognize the value of these kits, as they play an indispensable role in sustaining productivity and reducing maintenance costs over time. By focusing on quality, precision, and expert installation, businesses can trust in the sustained performance of their hydraulic systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories