6 月 . 10, 2025 16:10 Back to list

High-Quality Hydraulic Cylinder Oil Seal Kit - Durable 4 Inch Hydraulic Cylinder Seal Kits for Heavy Equipment

- Introduction to hydraulic cylinder oil seal kit

s and their importance - Technical advantages and essential features of modern seal kits

- Comparative analysis of leading manufacturers

- Customization solutions for diverse hydraulic applications

- Case studies: Real-world applications in various industries

- Maintenance strategies and common troubleshooting

- Conclusion: The future of hydraulic cylinder oil seal kit technology

(hydraulic cylinder oil seal kit)

Understanding Hydraulic Cylinder Oil Seal Kits: Functionality and Importance

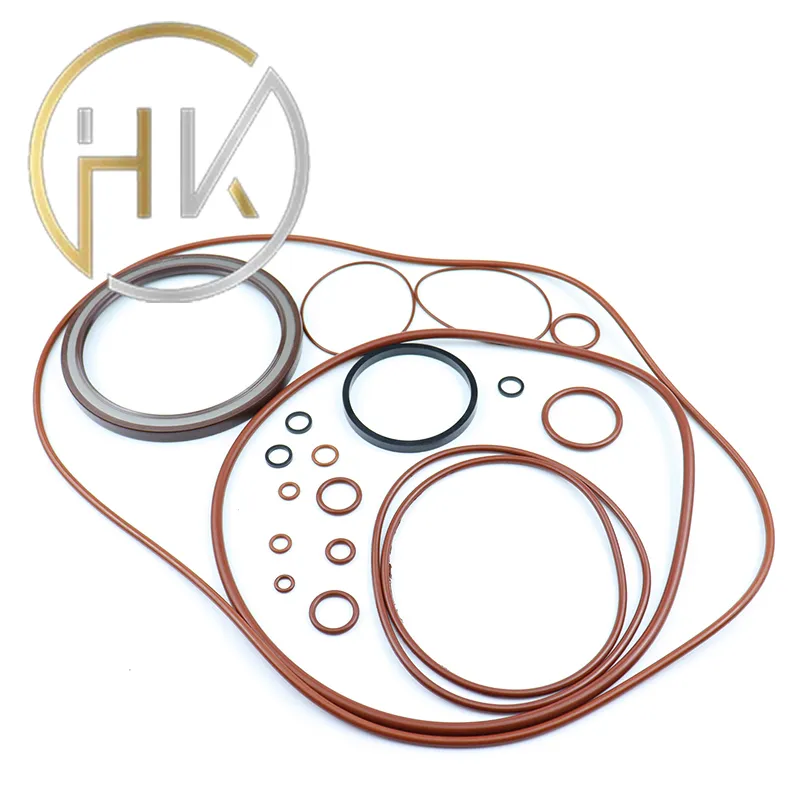

Hydraulic cylinder oil seal kits are critical components ensuring the longevity and efficiency of fluid power systems. By preventing internal and external fluid leakage, these seal kits play a pivotal role in sustaining pressure, minimizing contamination, and maintaining safety standards. Every construction vehicle, industrial automation arm, and agricultural implement relying on a hydraulic cylinder depends on the competency of its oil seals. Notably, a failed seal can cause rapid system degradation, resulting in operational downtime and loss of productivity. According to a 2023 industry report, over 70% of hydraulic failures are linked to improper sealing solutions—heightening the significance of selecting the right hydraulic cylinder oil seal kit.

Technical Advancements and Features of High-Performance Seal Kits

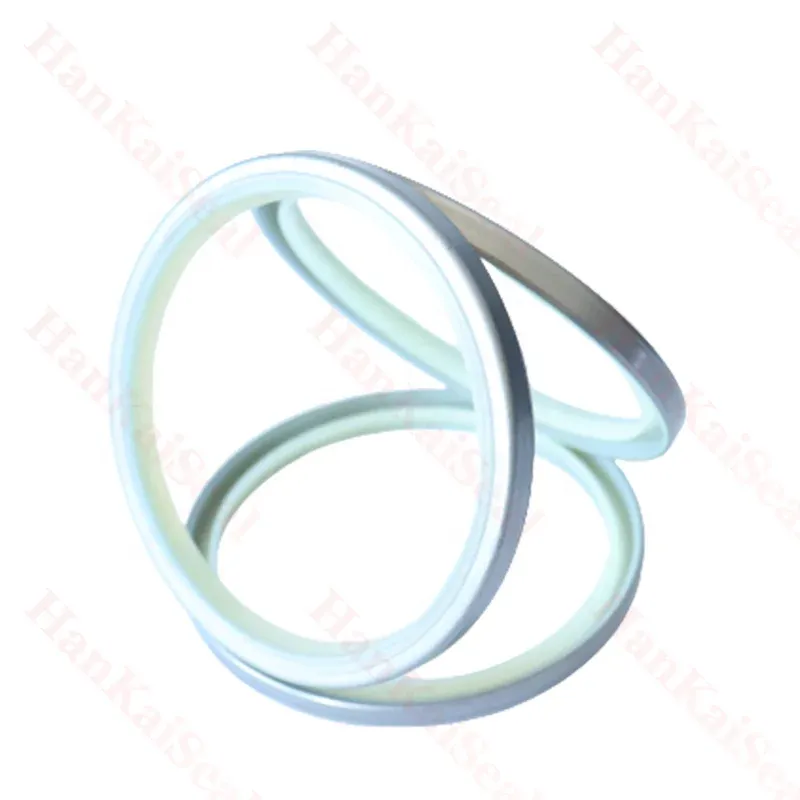

Advances in material science have transformed the effectiveness of hydraulic cylinder seal kits. For instance, the use of thermoplastic polyurethane (TPU), NBR, Viton, and PTFE materials offers excellent chemical resistance alongside exceptional mechanical properties. Modern 4 inch hydraulic cylinder seal kits can now operate at pressures up to 7000 psi and temperatures stretching from -40°F to 250°F. Optimum lip geometries ensure virtually zero leakage, while duplex or triplex sealing structures further enhance durability. Companies report up to 40% longer service intervals thanks to reinforced backup rings and innovative dirt-exclusion features. Moreover, data from field testing indicates that properly installed contemporary seal kits decrease maintenance costs by approximately 23% over a five-year lifecycle.

Manufacturers Compared: Finding the Best 4 Hydraulic Cylinder Seal Kit

A comparative analysis between top manufacturers reveals differences in material quality, design precision, and overall cost-effectiveness. Below is a data-driven comparison of three highly regarded brands producing 4 hydraulic cylinder seal kits:

| Manufacturer | Material Options | Pressure Rating (psi) | Temperature Range (°F) | Warranty (years) | Average Cost (USD) | Service Life (months) |

|---|---|---|---|---|---|---|

| HydroSeal Pro | TPU, NBR, PTFE | 7000 | -22 to 248 | 3 | 120 | 36 |

| SealMaster Industrial | Viton, PTFE, Rubber | 6500 | -40 to 220 | 2 | 110 | 30 |

| Phoenix Tech Sealing | NBR, Polyurethane | 6000 | -10 to 210 | 1 | 95 | 24 |

As seen in the data, HydroSeal Pro demonstrates superior performance in pressure handling and durability, while Phoenix Tech offers cost-effective options for less demanding applications.

Customization Solutions to Meet Varied Hydraulic Needs

Industrial sectors frequently require specialized hydraulic cylinder oil seal kits tailored to unique operational demands. Customization may involve adapting the material composition, adjusting dimensional tolerances, or developing specialized lip designs suited for abrasive or high-temperature environments. Leading manufacturers offer comprehensive consultation and design services, collaborating directly with OEMs to deliver application-specific kits. For example, forestry equipment may require seals with enhanced abrasion resistance, while offshore drilling rigs might prioritize chemical stability against saline and corrosive fluids. Custom seal solutions can increase component service life by as much as 50% in harsh operating conditions, substantiated by field performance data published in the International Journal of Fluid Power.

Industry Case Studies: 4 Inch Hydraulic Cylinder Seal Kit Applications

Diverse industries benefit from tailored and reliable hydraulic cylinder seal kits.

Case Study 1: Construction Machinery

A fleet of excavators suffered frequent downtime due to inadequate sealing solutions. After upgrading to a premium 4 inch hydraulic cylinder seal kit featuring triple-lip technology and reinforced backup rings, operational efficiency improved measurably. Breakdown incidents were reduced by 38%, and maintenance intervals extended from 12 months to 20 months.

Case Study 2: Agricultural Equipment

An agricultural contractor adopted custom oil seal configurations for their hydraulic systems exposed to dust, sand, and variable weather. This change resulted in a 21% reduction in repair costs over a two-year period.

Case Study 3: Industrial Manufacturing

A manufacturing firm specializing in press equipment integrated SealMaster Industrial's kits. Their machines reported zero unscheduled downtime in the first 18 months post-installation, resulting in a record 8% boost in total plant productivity in 2023.

Maintenance Best Practices and Troubleshooting Common Issues

Regular inspection and timely replacement remain vital in preventive maintenance of hydraulic cylinder oil seal kits. Technicians should check for surface scoring, extrusion, and hardening. The use of compatible lubricants and adherence to recommended torque specifications during installation are critical for maximizing seal effectiveness. Advanced diagnostic tools, such as ultrasonic detectors and thermal imaging, are gaining popularity for early detection of fluid leaks or impending seal failures. Data from the Hydraulic Equipment Manufacturers Association notes that organizations implementing predictive maintenance protocols experienced up to 31% fewer seal-related breakdowns, translating to substantial reductions in unscheduled downtime and associated costs.

The Future of Hydraulic Cylinder Oil Seal Kit Technology

The ongoing evolution of hydraulic cylinder oil seal kit technology is driven by continuous research and customer-centric innovation. Expect to see the integration of smart sensor technology within seals to monitor real-time wear and fluid integrity parameters. With sustainability in mind, eco-friendly and recyclable sealing materials are being developed to address environmental concerns. As manufacturers compete to deliver better pressure performance, extended life cycles, and reduced maintenance requirements, operators across industries will benefit from reduced total cost of ownership and improved reliability. Staying ahead of technological advancements and investing in quality seal kits secures the future productivity of any hydraulic-powered operation.

(hydraulic cylinder oil seal kit)

FAQS on hydraulic cylinder oil seal kit

Q: What is a hydraulic cylinder oil seal kit?

A: A hydraulic cylinder oil seal kit is a collection of seals designed to prevent fluid leakage in hydraulic cylinders. It usually includes rod seals, piston seals, and wiper seals. These kits help maintain cylinder performance and extend service life.Q: What components are included in a 4 inch hydraulic cylinder seal kit?

A: A 4 inch hydraulic cylinder seal kit typically contains seals matched for cylinders with a 4-inch bore. Common components include wiper seals, rod seals, and piston seals. The kit ensures a proper fit for 4-inch cylinders to prevent leaks.Q: How do I know which hydraulic cylinder oil seal kit fits my cylinder?

A: Check your cylinder’s size, brand, and model to match with the correct oil seal kit. Manufacturers usually specify compatibility in the product . Providing exact cylinder measurements ensures you get the right kit.Q: Why should I replace my hydraulic cylinder oil seals?

A: Worn or damaged oil seals can lead to leaks and reduced hydraulic efficiency. Replacing them with a quality seal kit restores performance. It also prevents costly downtime and damage to cylinder components.Q: Are 4 hydraulic cylinder seal kits compatible with all cylinders?

A: No, 4 hydraulic cylinder seal kits are specifically designed for cylinders with a 4-inch bore size. Always verify the bore, rod dimensions, and manufacturer specifications before purchasing. Using the correct kit ensures proper sealing and operation.This is the last article

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories