1 月 . 20, 2025 07:16 Back to list

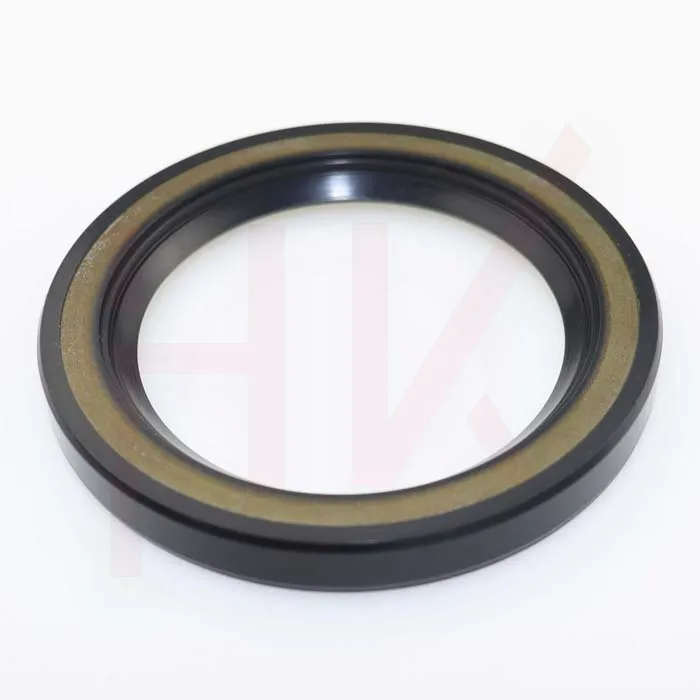

high speed rotary shaft seals

Trustworthiness in high-speed rotary shaft seals is further solidified through meticulous after-sales support and advisory services. Manufacturers who stand behind their products typically offer comprehensive support systems designed to address potential issues swiftly. They provide maintenance tips, troubleshooting guides, and in some cases, customized training for operators to maximize seal longevity and efficiency. For industrial operations, overlooked aspects like seal failures can lead to catastrophic outcomes including unplanned downtimes and expensive repairs. Therefore, the investment in high-quality, high-speed rotary shaft seals amounts to securing peace of mind. These seals not only ensure the smooth operation of machinery but also protect the substantial investments made in advanced industrial systems. Finally, the continuous evolution in seal technology promises exciting advancements. Ongoing research into smart seals equipped with sensors for condition monitoring and diagnostic purposes is paving the way for predictive maintenance strategies. As technology progresses, the proactive capabilities of high-speed rotary shaft seals will likely become a staple in industrial maintenance protocols, minimizing unforeseen breakdowns and maximizing equipment uptime. In conclusion, understanding the intricacies of high-speed rotary shaft seals entails acknowledging their indispensable role in enhancing machine performance and reliability. With their expertise, manufacturers provide customized sealing solutions that uphold the highest standards of professionalism and trustworthiness. Consequently, these components are pivotal in fortifying the operational backbone of modern industry, ultimately contributing to a more streamlined, efficient, and robust industrial landscape.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories