1 月 . 31, 2025 00:33 Back to list

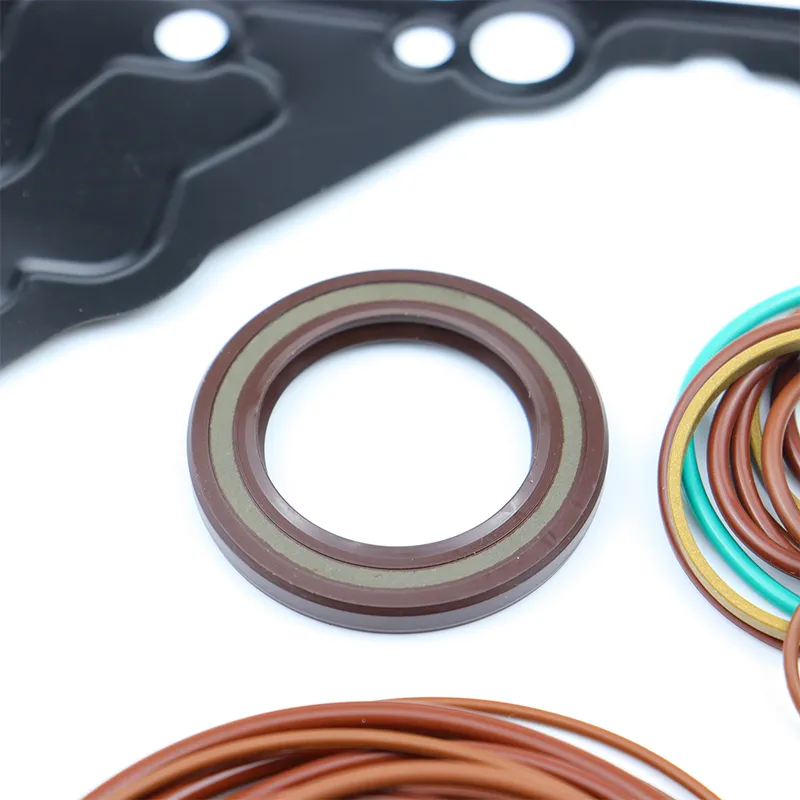

gear pump seal kit

Choosing the right gear pump seal kit requires a thorough understanding of the pump's operational environment and fluid characteristics. Expertise in material science and mechanical engineering is crucial in selecting the appropriate seals that can withstand the specific chemical composition, temperature range, and pressure levels within the system. Collaborating with manufacturers and industry experts can provide valuable insights into the best seal kit choices. These experts guide users in understanding seal compatibility, ensuring that the selected kits align with the pump's mechanical specifications and operational requirements. Installation and Maintenance Expertise Proper installation of gear pump seal kits is as crucial as choosing the right kit. Incorrect installation can compromise the seal's effectiveness, leading to leaks and operational inefficiencies. It is, therefore, vital to adhere to manufacturer guidelines and possibly engage professional services for seal kit installation. Training personnel in the best practices for seal installation and maintenance also adds an extra layer of reliability and trustworthiness to the operation. Moreover, regular maintenance checks are imperative in identifying wear and tear of the seal components. Expertise in detecting early signs of seal failure can prevent untimely breakdowns and ensure the longevity of the gear pump. Professionals armed with industrial experience understand the nuances of seal wear, providing actionable insights into preemptive seal replacements. Trustworthiness Through Quality Assurance Ensuring the trustworthiness of gear pump operations lies in consistently using top-tier seal kits. Partnering with reputable manufacturers who uphold stringent quality assurance processes guarantees that the seal kits meet industrial standards and operational demands. High-quality materials, alongside meticulous manufacturing processes, reduce the likelihood of seal failure, reinforcing operational integrity. Building trust also involves transparent communication with suppliers, understanding the warranty, and service agreements related to seal kits. Establishing these relationships ensures a reliable supply chain and access to essential resources in the case of urgent replacements or queries. In conclusion, the selection, installation, and maintenance of gear pump seal kits are critical components in ensuring the efficient, reliable, and trustworthy operation of gear pumps. By leveraging expertise, adhering to best practices, and investing in quality assurance, operators can significantly enhance the operational lifespan and performance of their gear pumps, thereby achieving optimal results in their industrial applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories