10 月 . 11, 2024 12:14 Back to list

Understanding Gearbox Seals for Enhanced Performance and Longevity in Machinery Applications

Understanding Gearbox Seals An Essential Component in Mechanical Systems

Gearboxes play a crucial role in many mechanical systems, functioning to transmit power and control speed and torque. Within these complex assemblies, gearbox seals are essential components that ensure their efficient and reliable operation. This article will delve into the importance, types, and best practices for gearbox seals.

The Importance of Gearbox Seals

Gearbox seals are designed to prevent the leakage of lubricants and protect the internal components of the gearbox from external contaminants such as dirt, dust, and moisture. They serve multiple functions

1. Lubrication Retention Gearboxes require lubricants to reduce friction between moving parts. Seals help retain this lubricant, ensuring that the gears operate smoothly and efficiently.

2. Contaminant Prevention Dirt and moisture can significantly damage gearbox components. Seals create a barrier that helps keep these harmful elements out, thereby extending the lifespan of the gearbox.

3. Pressure Maintenance Some gearboxes operate under varying pressures. Seals help maintain this pressure, ensuring optimal function.

4. Operational Efficiency By preventing lubricant loss and keeping contaminants at bay, seals contribute to the overall efficiency of the gearbox, reducing the need for frequent maintenance.

Types of Gearbox Seals

Gearbox seals can be classified into several categories, each designed for specific applications and environments

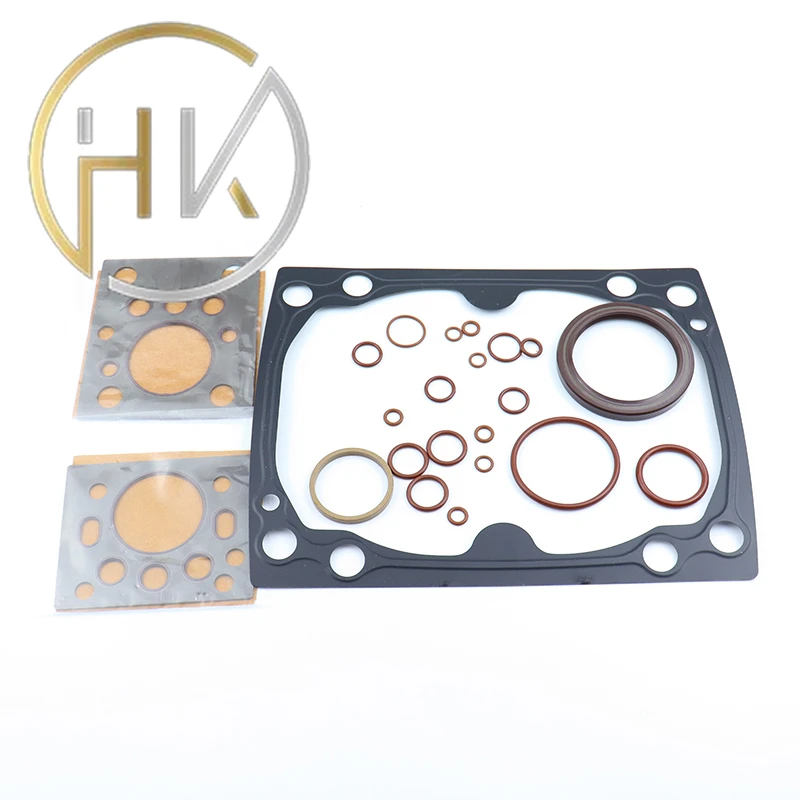

1. Lip Seals These are perhaps the most common type of seals used in gearboxes. They consist of a flexible lip that contacts the shaft, providing a tight seal. Lip seals are effective in preventing the leakage of oil and are suited for applications with moderate speeds and pressures.

2. O-Rings Made from elastic materials like rubber, O-rings are circular seals that fit into grooves and compress against a mating surface. They are versatile and used in various applications, including gearboxes, for their ability to maintain a reliable seal under moderate pressure.

gearbox seals

3. Mechanical Seals Used in applications where high pressure and temperature are present, mechanical seals consist of rotating and stationary components that create a seal. These are ideal for heavy-duty gearboxes and systems requiring a robust sealing solution.

4. Seal Washers Often used in conjunction with other seals, seal washers are flat or shaped components that help with sealing at bolt or screw interfaces, ensuring that lubricants remain contained.

Best Practices for Gearbox Seals

To ensure the longevity and performance of gearbox seals, following best practices is essential

1. Regular Inspection Gearbox seals should be inspected regularly for signs of wear or damage. Early identification of issues can prevent costly repairs and downtime.

2. Proper Installation Seals must be installed correctly to function as intended. Following manufacturer guidelines during installation ensures that seals fit properly, preventing leaks.

3. Appropriate Materials Selecting the right seal material is crucial, as it must withstand the specific operating conditions, such as temperature, pressure, and exposure to oils or solvents.

4. Lubricant Compatibility Ensure that the lubricants used in the gearbox are compatible with the materials of the seals to prevent degradation.

5. Replace Worn Seals Promptly Over time, seals can wear out. Prompt replacement of worn or damaged seals is vital to maintaining the operational integrity of the gearbox.

Conclusion

Gearbox seals may be small components in the grand scheme of mechanical systems, but they play a significant role in ensuring the functionality and durability of gearboxes. Investing in quality seals, adhering to best practices, and understanding their importance can lead to smoother operations, reduced maintenance costs, and a longer lifespan for mechanical systems. By prioritizing the care of gearbox seals, engineers and operators can enhance the reliability and performance of their machinery, paving the way for efficient and effective operations.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories