2 月 . 13, 2025 05:15 Back to list

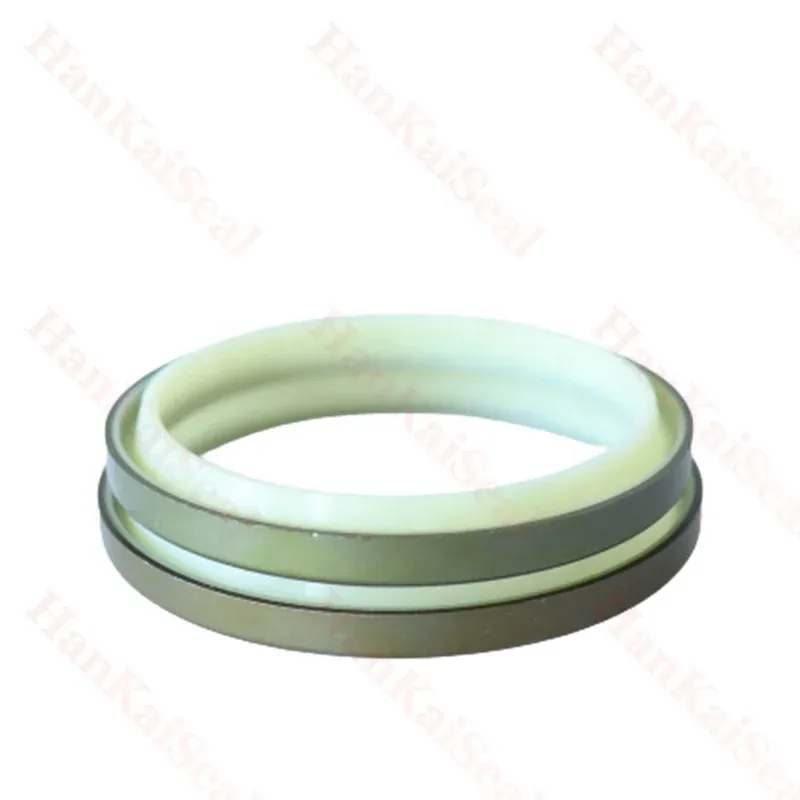

Standard High Pressure TCV Type Hydraulic Oil Seal

The installation of new seals must be done with meticulous attention to the specifications provided by the manufacturer. Using tools designed for seal installation can prevent damage and ensure a snug fit. Experience shows that applying a thin layer of appropriate grease can facilitate smoother application and better sealing effectiveness. Expertise dictates reassembly should follow the order of disassembly. Ensuring each component is aligned correctly prevents unnecessary force that could distort the cylinder’s operation. Reconnecting the hydraulic lines demands precision, ensuring all fittings are tightened to avoid any leaks. Once the boom cylinder is reassembled and reattached, it’s prudent to bleed the hydraulic system again. This prevents air pockets from disrupting the hydraulic pressure, a detail that underscores the authority and trustworthiness expected from an expert-level service. Conducting a test run of the excavator to verify the successful seal replacement is a step that validates the authority of the procedure. Evaluating the responsiveness of the boom cylinder and checking for any leaks is imperative to confirm that the replacement has restored its function. Maintaining the integrity of an excavator’s boom cylinder extends beyond the replacement process. Regular inspections and timely maintenance schedules can preempt issues, ensuring that seal replacements or repairs are infrequent and less intensive. Investing in quality materials and adhering to precise methods not only extend the life of the machinery but also fortify the trust clients place in those providing the maintenance service. The expertise and experience invested in such operations reflect professional authority and establish an unshakeable trustworthiness that is precious in the heavy machinery domain.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories