1 月 . 29, 2025 01:38 Back to list

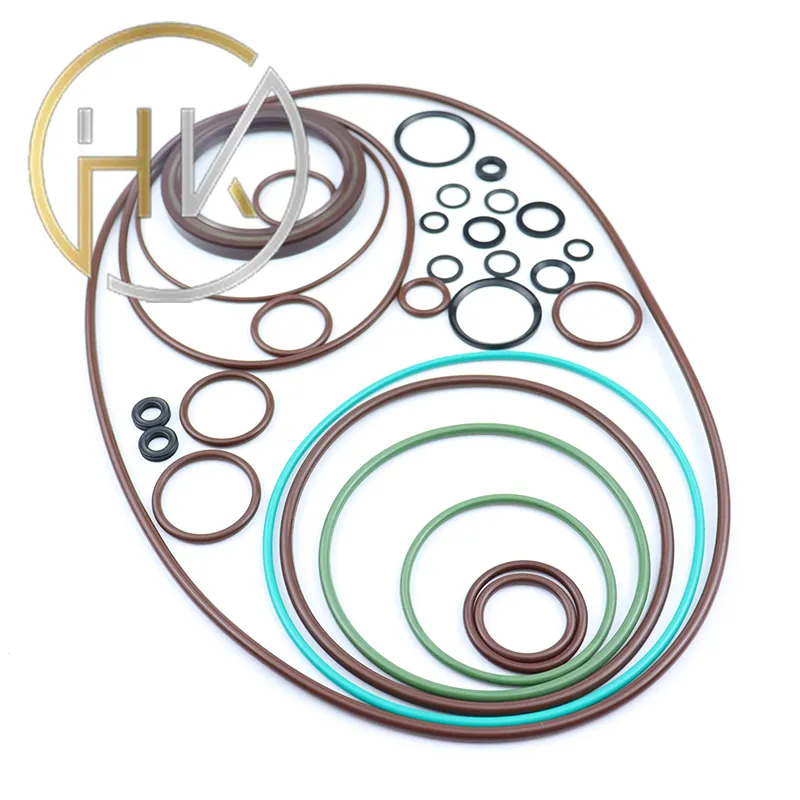

double wiper seal

Moreover, authoritative studies highlight the adaptability of double wiper seals in diverse applications. From being integral components in advanced robotic systems to playing vital roles in automotive subsystems, these seals are versatile. Their ability to conform to complex geometries and function effectively under fluctuating dynamics makes them invaluable. Researchers continue to underscore the importance of selecting seals that are tailor-fitted to specific applications, a factor that vastly enhances the overall performance and reliability of equipment. Trustworthiness in technical applications cannot be overstated, and double wiper seals provide assurance through their proven track record. In many instances, retrofitting existing machines with double wiper seals has been a strategic move for companies focusing on extending the lifecycle of their assets. Detailed case studies reveal that the strategic choice to employ double wiper seals corresponds with decreased incidences of leakage and corrosion, leading to smoother operations and less frequent interruptions. This trust in performance is validated by extensive field testing and feedback from key industry players who advocate for their use based on tangible results. In conclusion, the integration of double wiper seals is marked by their proven ability to enhance operational efficiency, their adaptability across various applications, and their capacity to uphold the integrity of sophisticated systems. As industries continue to push boundaries and demand more from their equipment, the role of robust sealing solutions, especially double wiper seals, becomes increasingly significant. By investing in these seals, companies are not just safeguarding their operations but are also stepping into a future of reduced maintenance costs and higher productivity.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories