1 月 . 29, 2025 01:14 Back to list

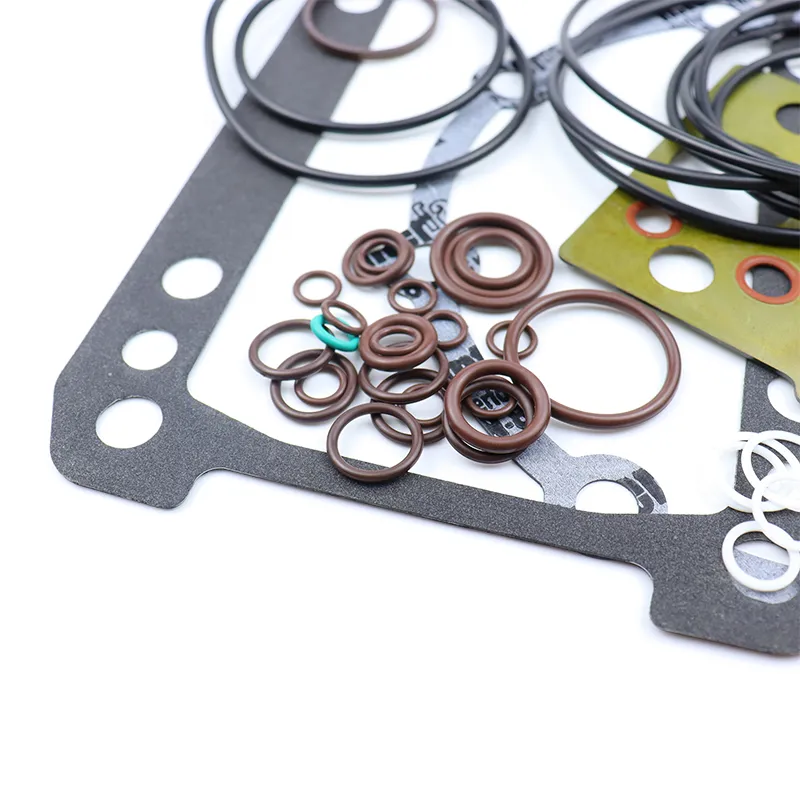

double lip wiper seal

From an expertise angle, choosing the correct material for double lip wiper seals is paramount. Common materials include various rubbers and polymers, selected based on the specific requirements of the application, such as temperature range, chemical exposure, and mechanical stress. Each material offers distinct benefits and limitations; thus, understanding the specific needs of the application site is essential for optimal seal performance. The authoritativeness of these seals in high-performance applications is well-documented. Industries ranging from automotive to aerospace rely on double lip wiper seals for their robust performance and reliability. These seals are often subjected to rigorous testing to ensure they meet stringent industry standards and can withstand the dynamic environments in which they operate. In terms of trustworthiness, double lip wiper seals have consistently demonstrated their value in extending the lifecycle of machinery components. Their design not only safeguards against environmental contaminants but also supports the efficient operation of machinery by ensuring that lubrication is maintained within necessary areas of the system. Manufacturers often accompany these products with detailed specifications and testing data to assure end-users of their performance characteristics. In conclusion, the double lip wiper seal is an indispensable component for anyone seeking to enhance the performance and reliability of their hydraulic or pneumatic systems. Its dual-lip design offers superior protection against contaminants while maintaining essential lubrication. Selecting the appropriate material and ensuring proper installation are critical steps in maximizing the potential of these seals. Their proven track record and endorsement by leading industry players stand as a testament to their effectiveness and reliability, making them a trusted choice for maintaining system integrity in demanding applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories