2 月 . 01, 2025 01:20 Back to list

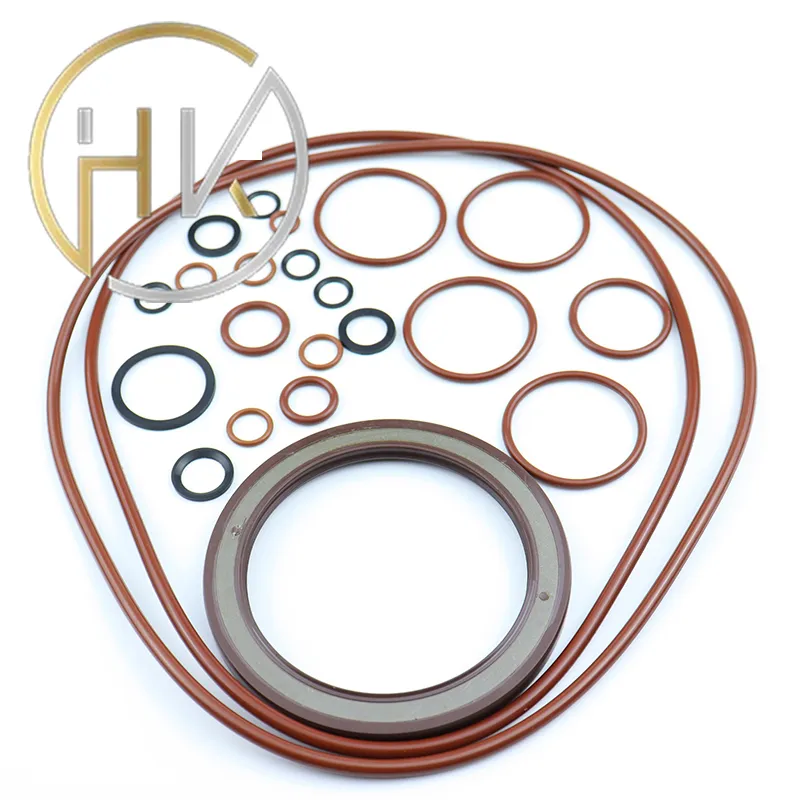

cylinder packing kits

Incorporating user experiences through reviews and case studies can also form a valuable part of the decision-making process. Users’ experiences often highlight practical insights into the performance and longevity of packing kits in real-world conditions. Access to such information offers an additional layer of confidence, as these firsthand accounts can reveal issues that might not be immediately apparent during the selection process. In terms of installation and maintenance, it is advisable to follow the manufacturer's guidelines to ensure the longevity and optimal performance of the packing kits. Proper installation techniques are pivotal, as even the best quality kits can fail without correct handling. This extends to regularly scheduled maintenance checks to ascertain that all components remain in prime condition, mitigating the likelihood of unforeseen downtimes. In conclusion, the selection and application of cylinder packing kits are not decisions to be taken lightly. By leveraging in-depth expertise, manufacturers’ reputations, and empirical user experiences, you can ensure that your choice not only suits the operational demands but also adheres to industry best practices. As this niche continues to evolve, staying informed about new materials and technologies will further enhance system reliability and efficiency. Remember, the right choice of cylinder packing kits can lead to improved performance metrics, extended machinery life, and substantial cost savings in industrial operations. Therefore, investing the time to select the appropriate kit is well worth the effort, grounding decisions in informed research, coupled with professional guidance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories