1 月 . 25, 2025 21:59 Back to list

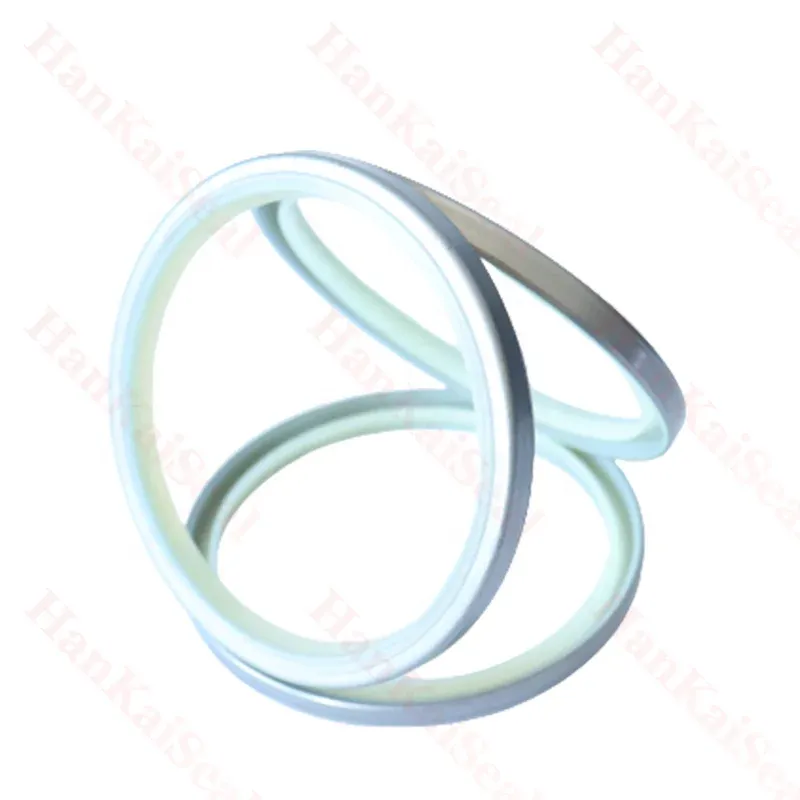

dkb seal

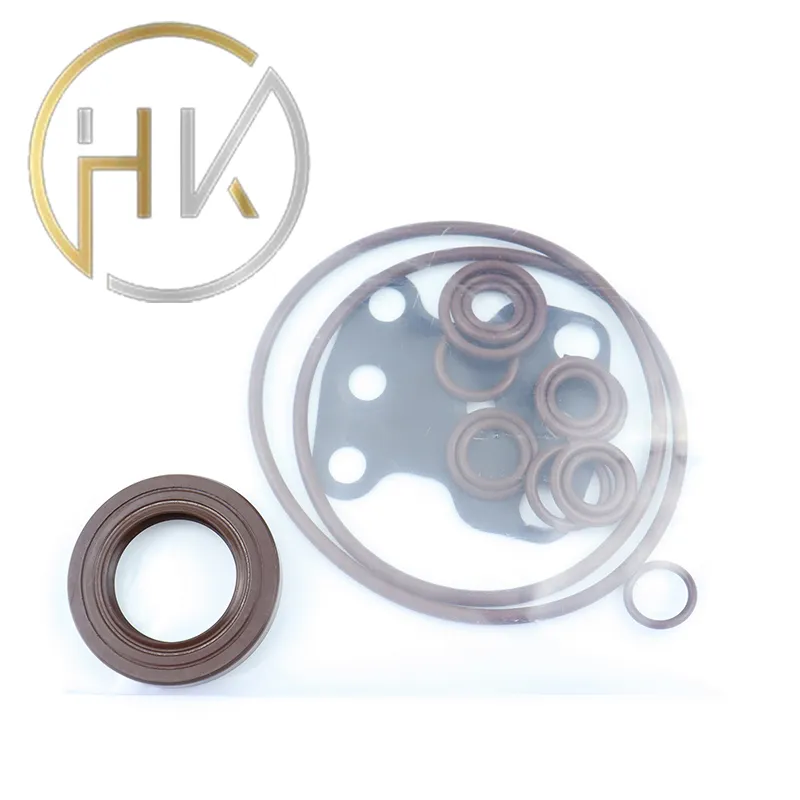

The market also presents options for custom seal kits, which are exceptionally beneficial for bespoke machinery that operates under unique conditions. These custom solutions are designed by taking meticulous measurements and requiring precise specifications, ensuring that every component of the seal kit fits perfectly for the settings they are intended for. This bespoke approach further guarantees reliability, as it considers specific use-cases that off-the-shelf products might not fully address. Moreover, regular maintenance schedules should incorporate inspections of these seals, with a keen eye for identifying wear and tear. Such diligence not only prolongs the life of the hydraulic system but also prevents unexpected failures. The role of the cross cylinder seal kit expands beyond immediate repairs—it represents an ongoing commitment to machine care and efficiency. For businesses looking to optimize their equipment operations, investing in high-quality cross cylinder seal kits means choosing durability, understanding system requirements, and establishing a proactive maintenance culture. It's a decision that underscores a commitment to operational excellence, minimizing unscheduled downtimes and maximizing productivity. My extensive background and firsthand experience with various hydraulic systems affirm that a well-chosen cross cylinder seal kit is not just a purchase, but an investment in reliability and performance. The journey of selecting the right seal kit can redefine efficiency and underscore the importance of precision in industrial operations. Through informed choices and expert guidance, these kits become more than just spare parts—they are critical allies in the quest for mechanical efficiency.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories